Advanced Properties and Applications

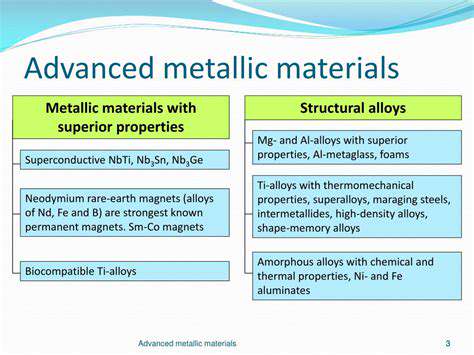

Modern metallic alloys represent a leap forward in material science, offering performance characteristics that far surpass conventional options. These specialized materials combine remarkable strength with impressive flexibility, alongside outstanding resistance to wear and environmental degradation. Such qualities have made them indispensable in fields ranging from aircraft manufacturing to medical device production.

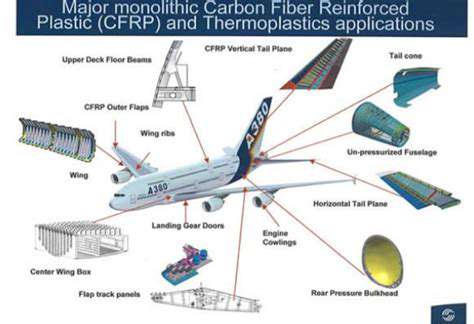

The ability to create lighter yet stronger components has revolutionized design approaches in transportation sectors, particularly aviation, where weight reduction translates directly to improved fuel economy and lower emissions. Additionally, their exceptional durability in challenging conditions ensures prolonged service life with minimal maintenance requirements.

Microstructure and Composition

The impressive capabilities of these engineered metals stem from their meticulously designed internal architecture. Scientists carefully manipulate the arrangement and interaction of microscopic components through precise additions of various metallic elements. This atomic-level engineering creates tailored material behaviors that meet specific application demands.

Decades of research have demonstrated that the secret to optimizing alloy performance lies in the intricate relationship between chemical makeup and microscopic structure. Contemporary analysis methods, including high-resolution imaging and crystallographic studies, provide invaluable insights into these complex material systems.

Manufacturing Processes

Fabricating these high-performance alloys demands specialized production methods capable of achieving exacting material specifications. Traditional approaches like precision casting coexist with innovative technologies such as powder-based forming and layered additive manufacturing. Each technique offers distinct advantages depending on the desired final product characteristics and economic considerations.

Cost and Availability

Premium pricing reflects the substantial research investments and complex production requirements for these advanced materials. While initial expenses may be higher, the long-term benefits including reduced replacement frequency and improved operational efficiency frequently justify the investment, particularly in mission-critical applications.

Supply limitations occasionally occur with highly specialized formulations, as manufacturing these materials requires exacting process controls and sometimes rare constituent elements. Production complexity increases proportionally with the sophistication of the desired material properties.

Future Trends and Research

Material scientists continue pushing boundaries, developing next-generation alloys capable of withstanding extreme conditions while maintaining structural integrity. These innovations promise to transform industries that operate in demanding environments, particularly aviation and power generation sectors.

Current investigations explore novel elemental combinations and processing methods to overcome existing limitations. Cutting-edge approaches include creating multi-scale structural hierarchies within materials to achieve unprecedented performance characteristics.

Bio-Based Materials: A Green Revolution

Bio-Based Materials: A Promising Alternative

The aviation sector, long dependent on petroleum-derived materials, is actively investigating plant-based alternatives. These sustainable options, sourced from agricultural products and microbial processes, represent a significant step toward eco-friendly manufacturing. This transition responds to increasing environmental awareness and the imperative to develop renewable material sources.

Beyond ecological benefits, biological materials frequently demonstrate performance characteristics that rival or exceed conventional options, enabling innovative aircraft designs with potential performance improvements.

Sustainability Advantages of Bio-Based Materials

Incorporating biological materials into aircraft production dramatically lowers the carbon emissions associated with manufacturing and operation. Renewable sourcing reduces fossil fuel dependence while supporting circular economic models. This approach also addresses the environmental drawbacks of traditional industrial processes.

Additionally, biological material production typically requires less energy than conventional methods, resulting in lower emissions and reduced environmental impact throughout the product lifecycle.

Material Properties and Performance

Plant-derived polymers and natural fiber composites offer customizable properties suitable for various aviation applications. Their strength-to-weight ratios and durability often match traditional materials, enabling development of more efficient aircraft designs. Current research focuses on optimizing these characteristics for different structural applications.

Challenges and Future Research Directions

Despite their promise, biological materials face adoption barriers including production costs, manufacturing scale-up challenges, and performance verification under extreme flight conditions involving temperature fluctuations and mechanical stresses.

Future investigations will concentrate on developing more efficient production methods while conducting rigorous testing to validate material performance in realistic operating environments.

Integration into Existing Manufacturing Processes

Adopting biological materials requires modifying current production techniques. This includes developing new methods for forming, assembling, and finishing components. Significant efforts aim to incorporate sustainable materials into conventional aircraft designs with minimal operational disruption.

Economic and Societal Implications

The shift toward biological materials carries broader economic and social consequences. It can stimulate growth in sustainable manufacturing sectors, generate employment opportunities, and drive eco-innovation. This transition may also diversify supply chains and reduce geographic dependencies for critical materials.

The potential environmental benefits of biological materials in aviation are substantial. Sustained research investment, coupled with supportive policies and infrastructure development, will be crucial for realizing this potential and achieving more sustainable air transportation.