Customized Design and Reduced Lead Times

Tailored Solutions for Aerospace Applications

Additive manufacturing, often referred to as 3D printing, is revolutionizing aerospace design and production. With this technology, engineers can now create highly complex, customized parts that were previously impossible to manufacture using traditional methods. This tailored approach allows for optimized designs that minimize weight, enhance strength, and improve overall performance. The ability to produce bespoke components directly addresses the specific needs of each aerospace project, leading to significant advantages over mass-produced parts.

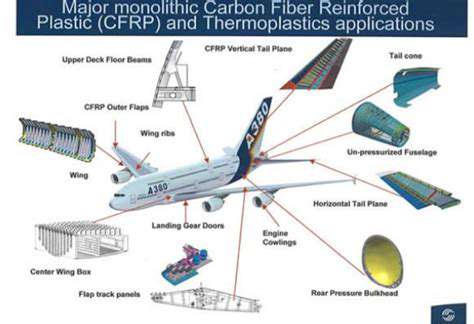

The customization capabilities extend beyond the physical shape of the part. Material selection becomes a crucial aspect of the design process. Engineers can incorporate specialized alloys or composites, precisely tailored to withstand the rigorous conditions encountered in flight. This precise control over material properties directly translates into enhanced safety margins and extended lifespan for the manufactured components. Additive manufacturing empowers aerospace engineers to truly push the boundaries of design innovation.

Streamlined Production and Expedited Delivery

One of the most compelling advantages of additive manufacturing in aerospace is the substantial reduction in lead times. The elimination of complex tooling and multi-step manufacturing processes dramatically shortens the time required to bring a component from design to production. This translates into significant cost savings and accelerated project timelines for aerospace companies, enabling them to respond more quickly to market demands and stay ahead of the competition.

Furthermore, the decentralized nature of additive manufacturing opens up new possibilities for on-demand production. This capability allows for the rapid prototyping of new designs and the creation of spare parts with minimal delay. This flexibility is particularly valuable in the aerospace industry, where rapid response to maintenance needs and emergency repairs are crucial for safety and operational efficiency. The potential for significantly faster turnaround times for critical components is a game-changer in the aerospace sector.

Additive manufacturing's ability to streamline the production process reduces logistical bottlenecks and minimizes material waste compared to traditional methods. These efficiencies contribute to a more sustainable and cost-effective approach to aerospace manufacturing, ultimately benefiting both manufacturers and end-users.

The reduced lead times and customized designs, combined with the potential for on-demand production, represent a significant leap forward in aerospace manufacturing. This shift promises to transform the way aerospace components are designed, produced, and deployed.

This streamlined process fosters a more agile approach to aerospace manufacturing, allowing for quicker adaptation to changing requirements and a better response to emerging challenges in the industry.

Challenges and Future Directions

Material Selection and Performance

A crucial aspect of additive manufacturing (AM) in aerospace is the selection of suitable materials. The performance characteristics of these materials, including strength, weight, fatigue resistance, and thermal stability, directly impact the structural integrity and operational efficiency of the manufactured components. Different AM processes are optimized for specific materials, and understanding these relationships is critical for realizing the full potential of AM in aerospace applications. This includes exploring new alloys and composites specifically designed for high-temperature environments and demanding load conditions that are often encountered in aircraft.

Furthermore, ensuring consistent material properties across different AM-produced parts is paramount. Variations in density, porosity, and microstructure can significantly impact the overall performance of the final product. Advanced characterization techniques and quality control measures are essential to address these potential inconsistencies and guarantee the reliability of AM-fabricated components in aerospace structures.

Process Optimization and Scalability

Optimizing AM processes for aerospace applications involves addressing challenges related to part complexity, scalability, and production speed. Achieving high build rates and consistent part quality while maintaining the intricate geometries often required in aerospace components poses significant technical hurdles. Research into innovative process parameters and strategies for controlling the build environment is vital to improve the efficiency and reliability of AM processes.

Scale-up of AM systems for large-scale aerospace production is another critical area for future research. Currently, many AM systems are limited in the size of parts they can fabricate. Developing larger and more robust AM systems with enhanced capabilities for producing large, complex aerospace components is essential for wider adoption in the industry.

Quality Control and Inspection

Ensuring the quality and reliability of AM-fabricated parts for aerospace applications necessitates robust quality control and inspection methods. Traditional inspection techniques may not be entirely suitable for the unique characteristics of AM parts, such as internal porosity and surface roughness. Advanced non-destructive testing (NDT) methods and computational tools are required to fully assess the integrity and performance of these components, while also reducing the overall cost and time required for inspection.

Furthermore, developing standardized quality control protocols and inspection procedures across different AM processes and materials is critical for achieving consistent quality and enabling seamless integration into existing aerospace manufacturing workflows. This will build trust and confidence in the reliability of AM-manufactured components.

Cost-Effectiveness and Manufacturing Integration

The cost-effectiveness of AM in aerospace applications is an important consideration for widespread adoption. Reducing the cost of materials, processing, and tooling is necessary to make AM a competitive alternative to traditional manufacturing methods. Exploring innovative cost-reduction strategies and improving the overall efficiency of AM workflows is essential for achieving a more economical approach.

Integrating AM into existing aerospace manufacturing workflows and supply chains requires careful planning and execution. Developing standardized interfaces, data exchange protocols, and improved collaboration between design, manufacturing, and quality control teams are essential for seamless integration and the efficient utilization of AM in aerospace production.

Design for Additive Manufacturing

Design considerations for AM-fabricated components differ significantly from traditional designs. Understanding the capabilities and limitations of various AM processes and materials is crucial for designing parts that can be successfully manufactured using AM techniques. Designing for manufacturability and incorporating features that aid in the AM process, such as support structures and internal cooling channels, can enhance the efficiency and cost-effectiveness of the manufacturing process.

Developing design tools and software that integrate AM capabilities and constraints into the design process is essential to maximize the benefits of AM in aerospace applications. This integration will enable designers to create innovative and optimized designs specifically for AM, further driving the potential for revolutionary improvements in aircraft design.