Predictive Maintenance: A Paradigm Shift in Industrial Operations

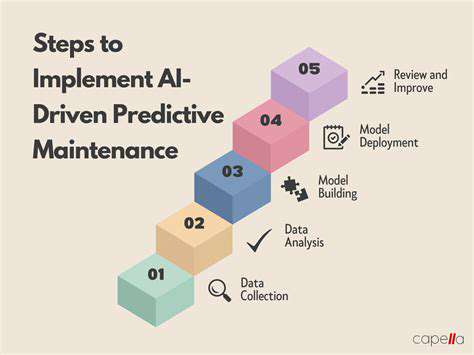

Predictive maintenance, powered by artificial intelligence (AI), is revolutionizing industrial operations by moving beyond reactive fixes to proactive maintenance strategies. This shift from reactive to proactive approaches significantly reduces downtime and operational costs. By analyzing vast amounts of data collected from various sources, AI algorithms can anticipate equipment failures before they occur, allowing for timely interventions and minimizing costly repairs.

Traditional maintenance practices often rely on predetermined schedules or reacting to breakdowns, leading to significant operational disruptions. Predictive maintenance, however, provides a far more efficient and cost-effective solution.

Data Collection and Analysis: The Foundation of AI-Powered Predictions

A crucial aspect of predictive maintenance is the collection and analysis of data from various sources, including sensor readings, machine performance metrics, and operational logs. This data, often complex and voluminous, needs to be meticulously processed and analyzed to extract meaningful insights.

AI algorithms are specifically trained on this data to identify patterns and anomalies that can indicate potential equipment failures. Sophisticated machine learning models, such as neural networks and support vector machines, are used to uncover these hidden signals.

Machine Learning Algorithms: Uncovering Hidden Patterns

Machine learning algorithms are central to AI-powered predictive maintenance. These algorithms are trained on historical data to identify patterns and anomalies that correlate with equipment failures. The algorithms learn to recognize subtle signs of deterioration that might not be immediately apparent to human operators.

Predicting Equipment Failures with High Accuracy

AI models can predict equipment failures with a high degree of accuracy, enabling maintenance teams to schedule interventions before breakdowns occur. This proactive approach minimizes costly downtime and ensures optimal equipment performance.

By leveraging historical data and real-time sensor readings, AI systems can forecast the likelihood of failure, providing a clear picture of the equipment's health and remaining operational lifespan.

Improving Maintenance Strategies and Reducing Costs

Predictive maintenance allows for optimized maintenance strategies, reducing unnecessary interventions and maximizing equipment lifespan. This results in significant cost savings by minimizing downtime, reducing repair expenses, and preventing catastrophic failures.

Real-Time Monitoring and Alert Systems: Proactive Intervention

AI-powered systems enable real-time monitoring of equipment performance, allowing for immediate alerts when anomalies are detected. This proactive approach allows maintenance teams to intervene swiftly, preventing potential failures and minimizing disruptions to production.

Real-time monitoring provides a critical advantage by enabling rapid responses to emerging issues. This capability is crucial for ensuring continuous operation and preventing major equipment failures.

The Future of Industrial Maintenance: A Data-Driven Approach

The future of industrial maintenance is undeniably data-driven, with AI playing a pivotal role in optimizing maintenance strategies. Implementing AI-powered predictive maintenance systems offers numerous benefits, ranging from reduced downtime and operational costs to improved safety and environmental performance.

The integration of AI into industrial maintenance is poised to transform the way we approach equipment management, leading to more efficient, reliable, and sustainable operations in the future.

Automated Inspection and Defect Detection: Enhancing Accuracy and Speed

Improving Accuracy in Aircraft Component Inspections

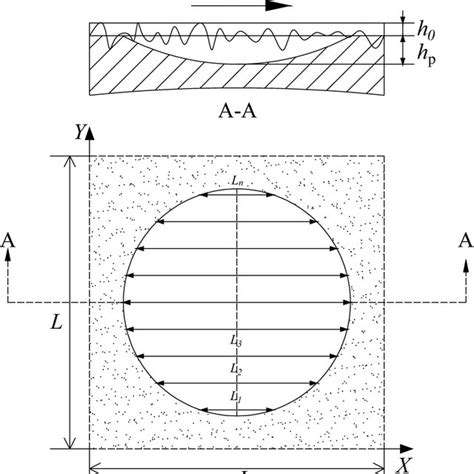

Automated inspection systems, leveraging AI algorithms, are revolutionizing the way we assess aircraft components for defects. These systems analyze high-resolution images and 3D models, meticulously scrutinizing surfaces for anomalies like cracks, corrosion, or material inconsistencies. The precise and consistent nature of AI-driven analysis significantly enhances the accuracy of defect detection compared to traditional methods, often reducing human error and increasing the reliability of the inspection process. This heightened accuracy ensures that potential issues are identified early, minimizing the risk of catastrophic failures and enabling more effective preventative maintenance strategies.

By automating the inspection process, AI systems can analyze an enormous volume of data much faster than a human inspector. This increased processing speed is critical for maintaining the efficiency and safety of aircraft operations. The ability to quickly and thoroughly evaluate components allows for more timely intervention and reduces the risk of delays or costly repairs.

Accelerating the Defect Detection Process

Traditional inspection methods often rely on time-consuming manual processes, slowing down the overall maintenance cycle. Automated systems, however, dramatically reduce this time lag by processing data in real-time. This accelerated pace is crucial for maintaining airworthiness standards and ensuring that aircraft remain operational. The speed and efficiency of AI-powered systems allow for quicker identification of defects, enabling proactive maintenance and reducing the potential for costly downtime.

Enhanced Detection of Subtle Defects

Human inspectors can sometimes miss subtle defects, especially when dealing with complex geometries or visually obscured areas. AI-powered systems, however, can analyze data with a level of detail and precision far surpassing human capabilities. This heightened sensitivity allows the system to detect anomalies that might otherwise go unnoticed, significantly improving the overall safety and reliability of the aircraft.

This ability to detect the smallest and most subtle defects is particularly important in critical areas of the aircraft, such as those involving structural integrity. The identification of these hidden issues is key to preventing future catastrophic failures and maintaining the safety of air travel.

Minimizing Human Error in Inspections

Human inspectors are susceptible to fatigue, distractions, and errors in judgment, which can lead to inaccurate assessments. Automated inspection systems, on the other hand, operate consistently and without these human limitations. This consistent performance minimizes the risk of errors, ensuring a more reliable and accurate inspection process. The elimination of human error leads to greater standardization and consistency in the detection of defects, which ultimately enhances the safety and reliability of aircraft.

Cost-Effectiveness of AI-Driven Inspection

While the initial investment in AI-powered inspection systems may seem substantial, the long-term cost-effectiveness is undeniable. By reducing inspection time, minimizing human error, and increasing the accuracy of defect detection, these systems ultimately decrease the likelihood of costly repairs and catastrophic failures. This translates to lower maintenance costs, reduced downtime, and significant cost savings over the lifespan of the aircraft. The benefits of reduced maintenance costs and improved efficiency ultimately benefit the entire aviation industry.

Optimizing Manufacturing Processes with AI: Enhancing Efficiency and Reducing Costs

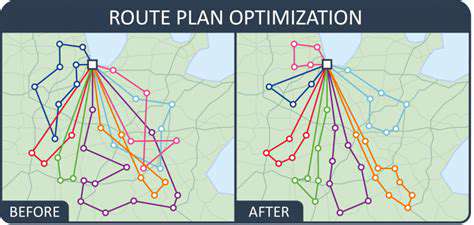

Streamlining Production Flow

Optimizing manufacturing processes frequently involves streamlining the production flow. This crucial step often involves analyzing current workflows and identifying bottlenecks, areas where production slows or stalls. A well-structured production flow minimizes wasted time and resources, leading to increased efficiency. By identifying and eliminating these bottlenecks, manufacturers can significantly reduce production costs and improve overall output.

Implementing lean manufacturing principles is often a core component of streamlining. These principles prioritize eliminating waste in all forms, from excess inventory to unnecessary movement of materials within the factory. This strategic approach to manufacturing fosters a culture of continuous improvement, encouraging employees to actively participate in identifying and solving problems.

Improving Material Handling

Efficient material handling plays a critical role in the overall success of a manufacturing process. This includes everything from transporting raw materials to the production line to moving finished goods to the warehouse. Poor material handling can lead to increased costs and delays, ultimately impacting the bottom line. Employing automated systems or optimizing existing processes can dramatically reduce these issues.

Careful consideration of storage and retrieval methods is essential for efficient material handling. This includes choosing the right storage solutions, such as racking systems, to ensure materials are readily accessible and organized. The right tools and equipment can also significantly reduce manual handling, contributing to a safer and more productive work environment.

Implementing Quality Control Measures

Implementing robust quality control measures is paramount to maintaining product quality and reducing defects. This involves establishing clear standards, testing procedures, and processes for identifying and correcting errors. Consistent quality control ensures customer satisfaction and reduces the need for costly rework or product recalls.

Investing in advanced quality control technologies, such as automated inspection systems, can significantly improve the accuracy and speed of quality checks. By integrating quality control into every stage of the production process, manufacturers can minimize errors and enhance the reliability of their products.

Utilizing Data Analytics for Process Improvement

Data analytics provides valuable insights into manufacturing processes, enabling manufacturers to identify areas for improvement and optimize their operations. Collecting and analyzing data on key performance indicators (KPIs), such as production time, defect rates, and resource utilization, can reveal patterns and trends that lead to actionable strategies. Using data analytics to understand and respond to these patterns can lead to significant efficiency gains.

By analyzing historical data and employing predictive modeling, manufacturers can anticipate potential issues and proactively address them. This data-driven approach fosters a culture of continuous improvement and allows manufacturers to make informed decisions that lead to enhanced profitability.