The aviation industry faces a critical juncture, where the need for sustainable practices is no longer a desirable option, but a fundamental requirement for the future. The environmental impact of air travel, including greenhouse gas emissions and noise pollution, is undeniable and necessitates a shift towards greener solutions. This shift demands a comprehensive approach, encompassing everything from aircraft design and manufacturing to operational efficiency and alternative fuels.

Technological Advancements in Aircraft Design

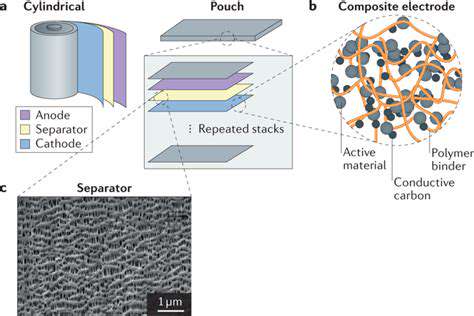

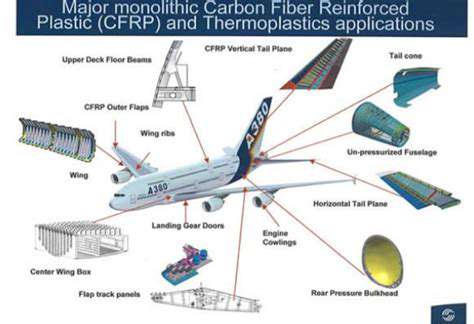

Significant strides are being made in aircraft design to minimize environmental footprints. This includes the incorporation of advanced materials, such as lightweight composites, and innovative aerodynamic designs aiming to reduce drag and fuel consumption. These advancements are crucial in achieving significant reductions in emissions per passenger kilometer.

Alternative Fuels: A Catalyst for Change

The development and deployment of alternative fuels are pivotal in the transition to sustainable aviation. Biofuels derived from sustainable sources, as well as synthetic fuels produced from renewable electricity, offer promising avenues for reducing reliance on fossil fuels. The challenge lies in scaling up production to meet the demands of the global aviation network.

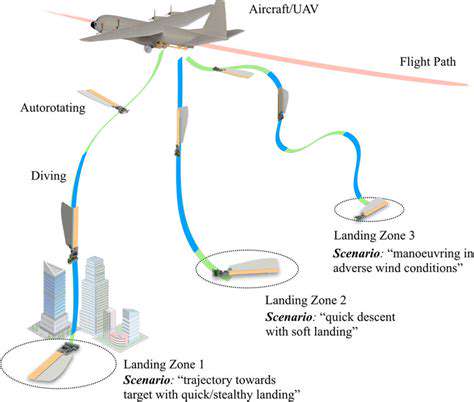

Operational Efficiency and Optimization

Optimizing flight paths, reducing idling times, and implementing more efficient air traffic management systems are crucial elements in minimizing fuel consumption and emissions. These operational improvements, while seemingly small, can collectively yield substantial environmental benefits. Improved maintenance schedules and aircraft condition monitoring further contribute to operational efficiency.

The Role of Sustainable Materials

The use of sustainable and recycled materials in aircraft construction is gaining significant momentum. This approach not only minimizes the environmental impact of manufacturing but also promotes a circular economy within the aviation industry. Using recycled materials can also dramatically reduce the overall environmental footprint of the aircraft.

The Impact on Passenger Experience

The transition to sustainable aviation shouldn't compromise the passenger experience. Innovations in aircraft design and operational efficiency can actually enhance the overall experience, potentially through quieter cabins, smoother rides, and more efficient travel times. Modernization can lead to a better customer experience without sacrificing environmental sustainability.

Government Policies and Industry Collaboration

Government policies play a critical role in supporting the development and adoption of sustainable aviation practices. Incentives for research and development, as well as regulations regarding emissions and fuel standards, are essential for encouraging the transition. Collaborative efforts between governments, airlines, and research institutions are essential to accelerate the pace of change and ensure a smooth transition towards a greener future for air travel.

Before storing carrots, it's crucial to thoroughly wash them under cold running water. This removes any dirt, soil, or debris that could spoil the carrots over time. Pay close attention to the roots, ensuring all traces of earth are removed. Once washed, use a sharp knife to trim the ends of the carrots. This not only improves their appearance but also helps prevent moisture buildup, a significant contributor to spoilage. Properly washing and trimming is the first critical step in achieving long-term carrot freshness.

Optimizing Maintenance Facility Operations

Preventive Maintenance Strategies

Implementing robust preventive maintenance strategies is crucial for optimizing maintenance facility operations. These strategies go beyond simply reacting to breakdowns. Proactive maintenance, scheduled inspections, and component replacements based on estimated lifecycles significantly reduce unplanned downtime and extend the lifespan of equipment. This proactive approach minimizes the risk of catastrophic failures, thereby ensuring consistent facility operation and maximizing output.

A key component of preventive maintenance is establishing a comprehensive maintenance schedule. This schedule should be tailored to the specific equipment and its operating conditions. Regular inspections, lubrication, and cleaning routines, according to the manufacturer's recommendations and facility-specific data, are essential. This meticulous approach ensures early detection of potential issues, allowing for timely intervention and avoiding costly repairs later.

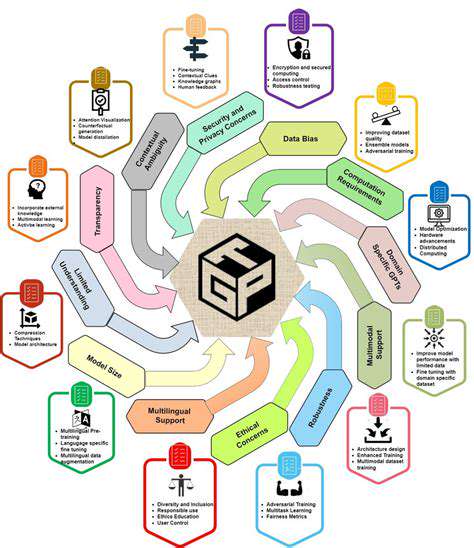

Predictive Maintenance Technologies

The integration of predictive maintenance technologies is revolutionizing facility operations. Sensors and data analytics enable real-time monitoring of equipment performance, identifying subtle changes that might indicate impending failures. This capability allows for proactive maintenance interventions, preventing costly breakdowns and maximizing equipment uptime.

Implementing predictive maintenance solutions requires a thorough understanding of the equipment's operating parameters. Analyzing sensor data from various equipment components can identify patterns and predict potential failures. This data-driven approach enables a more precise and efficient maintenance schedule, optimizing resource allocation and minimizing downtime.

Staff Training and Skill Development

Investing in comprehensive training programs for maintenance staff is paramount. A skilled workforce is essential for implementing effective maintenance strategies and ensuring the safety of facility operations. Training should cover not only basic maintenance procedures but also advanced techniques, including the use of specialized tools and equipment.

Upskilling the maintenance team with knowledge of predictive maintenance technologies and data analysis is essential. This empowers them to effectively interpret sensor data, identify potential issues, and implement timely interventions. This knowledge transfer is crucial for optimizing maintenance facility operations.

Facility Layout and Design

Optimizing the layout and design of the maintenance facility can significantly impact efficiency. A well-organized layout ensures that equipment is easily accessible for maintenance and repair, reducing the time and resources required for these tasks. Clear pathways, designated storage areas, and proper ventilation contribute to a safer and more efficient workspace.

Supply Chain Management

An efficient supply chain for maintenance parts and materials is crucial to maintaining smooth operations. Establishing reliable relationships with suppliers, ensuring timely delivery of parts, and maintaining adequate inventory levels are critical for minimizing delays and ensuring uninterrupted maintenance activities. Effective supply chain management prevents disruptions to the maintenance process and minimizes costs associated with procurement and delays.

Budgeting and Resource Allocation

Developing a realistic and adaptable budget for maintenance activities is essential. This budget should account for both planned and unplanned maintenance, including spare parts, labor costs, and potential emergencies. Prioritizing maintenance activities based on risk assessment and cost-benefit analysis ensures that resources are allocated effectively, optimizing the return on investment.