Introduction to AI-Powered Aerospace Design

Defining the Landscape of AI in Aerospace

Artificial intelligence (AI) is rapidly transforming various sectors, and aerospace design is no exception. AI's ability to process vast datasets, identify complex patterns, and make predictions is revolutionizing the traditional design process. This introduction will explore how AI is impacting the optimization of aerospace designs, from conceptualization to final production, examining its potential benefits and challenges. It's crucial to understand that this isn't simply about automating existing tasks; it's about fundamentally rethinking how we approach design challenges.

The integration of AI tools allows engineers to analyze intricate aerodynamic forces, simulate different materials and structures, and predict performance under various conditions with unprecedented accuracy. This empowers designers to explore a wider range of design possibilities and explore previously unattainable solutions, leading to more efficient and effective aircraft designs.

AI-Driven Simulation and Modeling

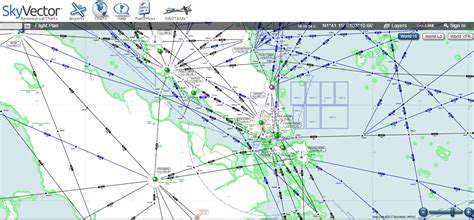

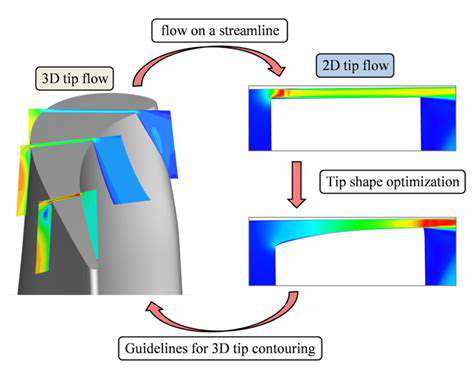

One of the key applications of AI in aerospace design is its ability to accelerate and enhance the simulation and modeling process. Traditional methods often rely on lengthy and resource-intensive simulations. AI algorithms can analyze massive datasets of historical data, flight tests, and computational fluid dynamics (CFD) simulations to create highly accurate models of complex aerodynamic phenomena and structural responses. This allows engineers to explore a wider range of design options and identify potential issues early in the design cycle.

Optimizing Material Selection and Structural Design

AI excels at identifying optimal material combinations and structural layouts for aerospace components. By analyzing the performance characteristics of various materials under different stress conditions, AI algorithms can predict the most suitable material for a specific application, minimizing weight and maximizing strength. This optimization can significantly reduce fuel consumption and increase the overall efficiency of the aircraft.

The ability to predict the behavior of complex structures under various loads and conditions allows for the design of lighter, stronger, and more durable components. This is crucial in aerospace design where weight reduction is critical for performance and cost-effectiveness.

Predictive Maintenance and Enhanced Safety

AI's predictive capabilities extend beyond the design phase, offering significant advantages in operational efficiency and safety. By analyzing sensor data from aircraft during flight, AI can predict potential maintenance needs and proactively schedule repairs, reducing downtime and ensuring the safe operation of the aircraft. This approach is crucial for minimizing maintenance costs and maximizing operational efficiency.

The Future of AI in Aerospace Design

The integration of AI into aerospace design is still in its early stages, but the potential for innovation is immense. Future advancements in AI will likely involve more sophisticated machine learning algorithms, enabling even more complex simulations and analysis. We can anticipate AI-powered design tools that can generate innovative designs based on specified requirements, automatically optimizing various aspects of the design process. Further research in AI will inevitably lead to more efficient and safer aircraft, and this will have a profound impact on the aviation industry.

As AI continues to evolve, its role in aerospace design will undoubtedly become more critical, driving innovation and pushing the boundaries of what's possible in the aviation industry.

AI-Driven Computational Fluid Dynamics (CFD) Optimization

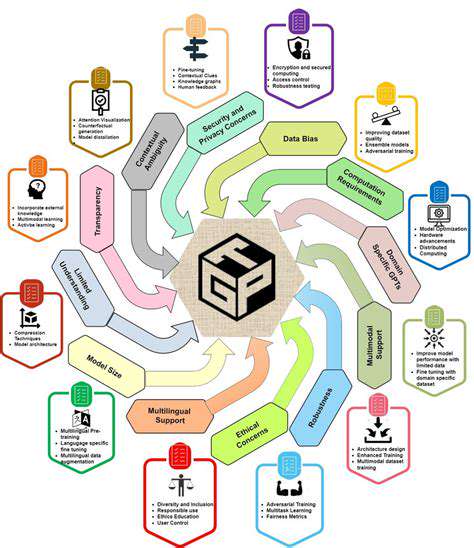

Understanding the Fundamentals of AI-Driven CFD

AI-driven computational fluid dynamics (CFD) is revolutionizing the field by leveraging the power of artificial intelligence to enhance and accelerate the analysis of fluid flow. This innovative approach allows for more complex simulations, which in turn unlocks a deeper understanding of intricate fluid behavior, something traditional CFD methods often struggle with. This advanced technology is particularly useful in optimizing designs for various applications, from aerospace engineering to biomedical research. By incorporating machine learning algorithms, AI-driven CFD can identify patterns and trends within vast datasets, leading to more accurate predictions and efficient simulations.

Traditional CFD methods rely heavily on numerical approximations and complex mathematical models to simulate fluid flow. However, these methods can be computationally expensive and time-consuming, especially when dealing with complex geometries or turbulent flows. AI, on the other hand, offers a promising pathway to streamline these processes, allowing engineers to explore a wider range of design possibilities in a shorter timeframe. This is particularly critical in industries where rapid prototyping and iterative design are paramount, such as aerospace and automotive design.

Applications and Impact of AI in CFD

The applications of AI in CFD are diverse and far-reaching. One key application is in the optimization of aircraft designs, enabling engineers to create more aerodynamic and fuel-efficient aircraft. By analyzing vast amounts of data on fluid flow around various aircraft configurations, AI can identify optimal shapes and parameters for improved performance.

Another significant application lies in the field of biomedical engineering. AI-driven CFD can be used to simulate blood flow in the human body, helping researchers understand the mechanisms of various diseases and develop innovative treatments. This includes modeling blood flow in arteries and veins, and predicting the impact of various medical interventions.

Furthermore, AI-driven CFD is proving valuable in the design of industrial equipment. By simulating fluid flow in complex machinery, such as pumps and turbines, engineers can optimize their performance, reducing energy consumption and increasing efficiency. This translates to significant cost savings and improved sustainability.

The impact of AI in CFD is undeniable, transforming the way we analyze and understand fluid dynamics. This technology is poised to revolutionize various industries, enabling more efficient designs, improved performance, and a deeper understanding of complex physical phenomena.

By automating and accelerating the simulation process, AI is opening up new possibilities in various fields, from aerospace to biomedical engineering. These advancements promise significant progress in areas where fluid flow plays a crucial role.

Material Selection and Structural Optimization with AI

Material Selection

AI algorithms are revolutionizing material selection in aerospace design. By analyzing vast datasets of material properties, manufacturing processes, and performance characteristics, AI can identify optimal materials for specific components. This process considers factors like strength-to-weight ratios, temperature resistance, and corrosion resistance, leading to lighter, stronger, and more durable aircraft structures. The ability to predict the long-term performance of different materials under various conditions is a significant advancement.

Traditionally, material selection was a time-consuming and iterative process. Engineers relied on extensive experimental testing and rule-of-thumb guidelines. AI, however, automates this process, dramatically reducing design cycles and allowing for a wider exploration of material combinations. This leads to significant improvements in design efficiency and ultimately, more competitive aircraft designs.

Structural Optimization

AI-powered structural optimization tools analyze complex structural designs to identify areas for improvement. These tools can simulate various loading conditions and predict stress distributions, enabling engineers to optimize the shape and arrangement of components for maximum strength and minimum weight. This process goes beyond simple weight reduction; it considers the intricate interplay of stress, strain, and fatigue life, leading to more robust and reliable designs.

Finite Element Analysis (FEA) Enhancement

AI significantly accelerates and enhances Finite Element Analysis (FEA), a crucial process in structural design. By learning from existing FEA data, AI can predict stress concentrations and failure points more accurately and efficiently than traditional FEA methods. This allows engineers to refine designs earlier in the process, minimizing costly revisions and ensuring the structural integrity of the aircraft.

Predictive Maintenance and Reliability

AI can predict potential material degradation and structural failures based on historical data and real-time monitoring. This predictive capability allows for proactive maintenance, reducing downtime and improving the overall reliability of aircraft. By analyzing sensor data, AI can identify subtle patterns indicative of stress or fatigue in critical components, enabling timely interventions and preventing catastrophic failures. This predictive maintenance capability is crucial for maintaining operational safety and efficiency.

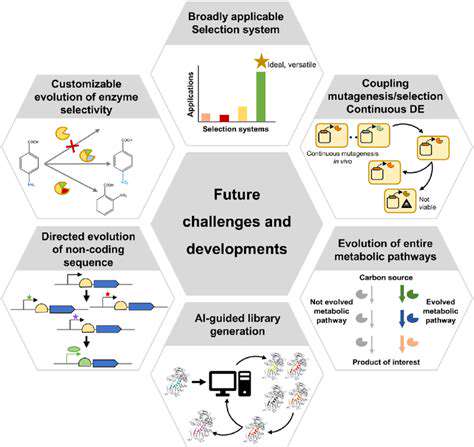

Design Exploration and Innovation

AI facilitates the exploration of novel design concepts and materials, pushing the boundaries of aerospace design. By analyzing vast datasets of design parameters, AI can identify hidden correlations and suggest innovative solutions that would be difficult or impossible to discover through traditional methods. This exploration of unconventional materials and structures opens up possibilities for significantly improved aircraft performance and reduced environmental impact. AI can also generate multiple design variations for optimization, resulting in a more robust and comprehensive design space.

Predictive Maintenance and Proactive Design with AI

Leveraging AI for Predictive Maintenance

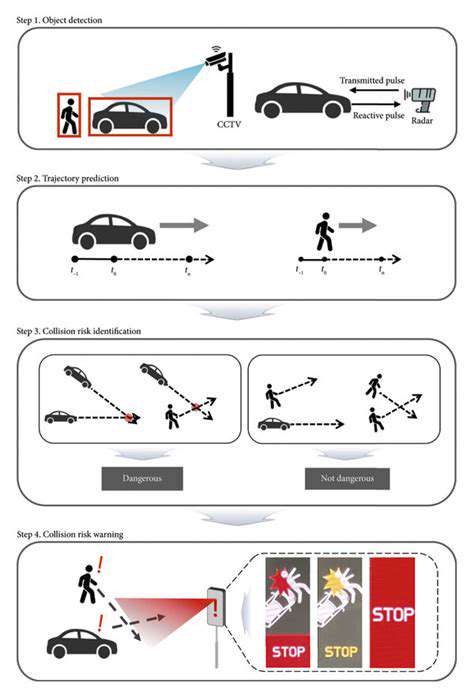

Artificial intelligence (AI) is revolutionizing the aerospace industry, particularly in predictive maintenance. By analyzing vast datasets of sensor data from aircraft, AI algorithms can identify subtle patterns and anomalies that indicate potential failures before they occur. This proactive approach minimizes downtime, reduces maintenance costs, and enhances operational efficiency. This predictive capability allows for more targeted maintenance schedules, optimizing resource allocation and preventing catastrophic failures.

The ability to forecast maintenance needs empowers engineers to schedule repairs during planned maintenance windows, eliminating the need for urgent interventions. This translates to increased safety and reliability, crucial aspects of aerospace operations. Through AI, the industry can move from reactive to proactive maintenance, dramatically improving operational performance.

Proactive Design Optimization with Machine Learning

AI-driven machine learning algorithms are transforming the design process. These algorithms can analyze numerous design parameters, identifying potential weaknesses and areas for improvement. By simulating various flight conditions and stress scenarios, AI can predict how a design will perform under different operating conditions, allowing for optimized design iterations before physical prototypes are created. This iterative approach significantly reduces the time and cost associated with the design cycle.

Predicting potential failure points allows engineers to incorporate robust safety margins from the initial design phase. This proactive approach reduces the risk of costly repairs or replacements during the aircraft's operational life. Ultimately, AI-powered design optimization leads to more reliable and efficient aircraft.

Data-Driven Insights for Enhanced Safety

AI algorithms excel at extracting meaningful insights from complex datasets generated by sensors on aircraft. By analyzing sensor data related to flight parameters, environmental conditions, and structural integrity, AI can detect anomalies and potential safety hazards. Early detection of these anomalies enables timely interventions, minimizing risks and ensuring the safety of passengers and crew. This data-driven approach to safety analysis is crucial in maintaining airworthiness standards.

The ability to identify and analyze patterns in sensor data allows for the development of more robust safety protocols and procedures. This continuous monitoring of aircraft performance using AI-powered analysis enhances the overall safety of air travel. AI's role in enhancing safety is undeniable and crucial in the aerospace industry.

AI-Powered Simulation for Reduced Testing Costs

Traditional aerospace design relies heavily on extensive and expensive testing. AI-powered simulations can replicate various flight conditions and stress scenarios, drastically reducing the need for physical prototypes and costly testing. This simulation technology allows engineers to explore a wide range of design options and assess their performance in different operational environments. The reduced testing costs lead to significant cost savings for aerospace manufacturers.

AI-driven simulations allow for virtual prototyping, enabling engineers to identify and address potential issues in the design phase. This iterative approach reduces the risk of costly design flaws and allows for more efficient resource allocation in the design process. The accuracy of these simulations is constantly improving, further solidifying their importance in aerospace design optimization.

AI in Material Selection and Optimization

Material selection is a critical aspect of aerospace design, directly impacting the aircraft's performance, weight, and cost. AI algorithms can analyze vast databases of material properties, considering factors like strength, weight, and cost. This allows for optimal material choices, leading to lighter and more efficient aircraft. AI's ability to predict material performance under various conditions is a significant advancement in the field.

Predicting material behavior under extreme conditions (e.g., high temperatures, extreme pressures) is a core competency of AI in this context. This allows for more informed and strategic material selection, ultimately contributing to the overall performance and reliability of the aircraft. AI's role in material selection is expected to grow as its capabilities become more sophisticated.

Streamlining the Design Process with AI Automation

AI can automate many tasks in the aerospace design process, from data analysis to generating design options. This automation significantly accelerates the design cycle and frees up engineers to focus on more complex tasks. The streamlined workflow enhances efficiency and productivity in design teams. AI's ability to automate repetitive tasks leads to increased output and faster turnaround times.

Automating tasks like data entry, preliminary design calculations, and even some aspects of structural analysis significantly reduces the risk of human error. The increased speed and accuracy of AI-driven automation translate to substantial improvements in the overall design process, leading to more efficient and cost-effective designs.

Improving Maintenance Scheduling and Resource Allocation

AI enables more precise maintenance scheduling by predicting potential failures based on real-time data analysis. This proactive approach optimizes maintenance resources, minimizing downtime and maximizing operational efficiency. The ability to predict maintenance requirements allows for more effective allocation of personnel and parts, leading to significant cost savings.

Predictive maintenance, powered by AI, reduces the frequency of unscheduled maintenance events, leading to a more reliable and efficient operation. The optimal allocation of resources, both human and material, improves the overall performance of the maintenance department, which is a major benefit in the aerospace industry.