Modern engineering increasingly relies on closed-loop systems, which outperform open-loop designs due to their adaptive nature. These systems continuously fine-tune operations through real-time monitoring, achieving unprecedented accuracy. From spacecraft navigation to factory robotics, this precision becomes indispensable where even minor errors carry catastrophic consequences. The marriage of constant data analysis with instant adjustments represents engineering's evolutionary leap toward perfection.

Feedback Mechanisms: The Heart of Closed-Loop Systems

At their core, these systems operate through an elegant dance of measurement and correction. Sensors act as the system's nervous system, perpetually evaluating performance against target metrics. Any discrepancy triggers calculated responses that nudge the system back toward optimal function. This cybernetic ballet occurs thousands of times per second in advanced implementations.

The system's intelligence lies not in its complexity but in its elegant responsiveness - a quality that demands exceptionally calibrated sensors and algorithms. When properly engineered, this feedback creates systems that anticipate disturbances before they cause deviation, much like a seasoned pilot correcting for turbulence.

Applications Across Diverse Industries

The versatility of closed-loop technology manifests across unexpected domains. Aircraft autopilots demonstrate their lifesaving potential, while smart thermostats showcase their energy-saving grace. In healthcare, these systems work miracles - insulin pumps now mimic pancreatic function with astonishing fidelity. Even wastewater treatment plants employ these principles to maintain perfect chemical balances despite fluctuating inputs.

Environmental applications reveal perhaps their most poetic use: closed-loop agriculture systems precisely deliver nutrients while recycling waste, creating sustainable ecosystems where linear systems would fail. This adaptability across scales - from microchips to megacities - confirms their revolutionary status.

Advantages and Challenges of Implementation

While offering transformative potential, these systems demand careful orchestration. Engineers must account for countless variables - sensor latency, algorithmic sensitivity, mechanical response times. The design phase becomes a high-stakes puzzle where each component's characteristics influence the entire system's stability. Initial costs often deter adoption, though the long-term savings in efficiency gains and error prevention typically justify the investment many times over.

Where conventional computers process binary states, quantum systems operate in multidimensional probability spaces. This represents not merely an upgrade, but a fundamental redefinition of information processing itself. By exploiting quantum superposition, researchers achieve computational feats that would require all Earth's classical computers working in concert for centuries.

Resource Acquisition and Utilization

Resource Acquisition Strategies

Establishing extraterrestrial habitats demands revolutionary resource paradigms. Future colonists must master extracting lunar regolith minerals and harvesting Martian atmospheric gases while perfecting near-total material recycling. This circular economy approach transforms waste streams into supply chains - a necessity when Earth resupply missions cost millions per kilogram. Autonomous prospecting drones will map subsurface resources with neutron spectrometers while self-replicating robotic miners construct the first infrastructure.

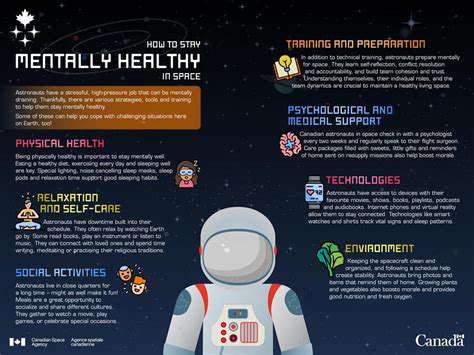

Energy Production and Distribution

Power systems must overcome extraordinary challenges: lunar nights lasting 14 Earth days, Martian dust storms obscuring sunlight for months. Compact fusion reactors may eventually provide baseline power, but innovative solutions like orbiting solar mirrors or subsurface geothermal taps offer interim solutions. The key innovation lies in creating resilient microgrids that automatically reconfigure during equipment failures - a lesson learned from Antarctic research stations.

Waste Management and Recycling

Advanced decomposition reactors will break down organic waste into constituent molecules while 3D printers reincorporate metallic scraps into new components. The ultimate goal: systems where yesterday's food packaging becomes tomorrow's habitat shielding through atomic-level reprocessing. Such closed ecological systems already demonstrate viability in BIOS-3 experiments, achieving 95% water and oxygen recycling.

Food Production and Agriculture

Vertical aeroponic farms will stack crop layers under spectrum-tuned LEDs, with root misters delivering nutrient solutions refined from human waste. Geneticists are developing potato varieties that thrive in regolith simulants, while mycologists engineer fungi to digest inedible plant matter into nutritious protein. These biotechnological advances promise to transform barren landscapes into productive ecosystems.

Water Acquisition and Purification

Drilling rigs will tap permafrost deposits while atmospheric water vapor harvesters condense moisture even in arid environments. Forward osmosis systems borrowed from naval technology will purify urine with 98% efficiency, and electrolysis will continuously regenerate breathable oxygen. Such systems already sustain crews aboard the International Space Station through years of continuous operation.

Material Science and Manufacturing

In-situ resource utilization (ISRU) technologies are pioneering methods to sinter lunar dust into construction materials using concentrated sunlight. Metallurgists develop aluminum extraction processes that work in vacuum conditions, while chemists formulate concrete alternatives from sulfur-rich Martian soil. These innovations will enable colonists to live off the land using locally sourced materials processed with minimal energy input.