Orbita, an emerging player in space exploration, has captured industry attention with its novel satellite deployment techniques and orbital solutions. Their pioneering reusable spacecraft designs and optimized launch protocols could slash space access costs by up to 60%, transforming accessibility for diverse applications. This breakthrough might redefine sectors like global communications, Earth observation, and extraterrestrial resource extraction by making space ventures economically viable for more participants.

Environmental stewardship forms a crucial part of Orbita's philosophy. The company invests heavily in sustainable spaceflight technologies, acknowledging that responsible development must accompany technological progress. This commitment reflects the increasing emphasis on ecological considerations across all technological sectors, including space exploration.

Analysts estimate Orbita's innovations could reduce orbital payload costs to unprecedented levels. Such reductions would benefit both commercial space enterprises and government space programs equally. We stand at the threshold of a paradigm shift in how humanity approaches off-planet activities and exploration.

Exploring the Applications: From Communication to Exploration

Orbita's technological advancements promise applications extending well beyond conventional satellite placement. For global connectivity, this could mean affordable satellite constellations bringing reliable internet to remote areas currently lacking digital infrastructure, potentially connecting millions of underserved users worldwide.

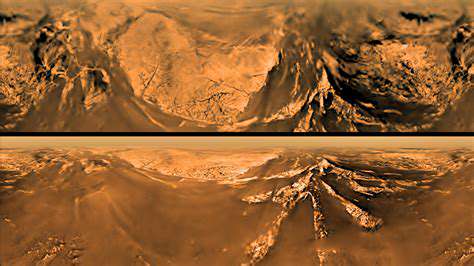

In scientific research, these cost reductions might enable more frequent planetary missions with advanced instrumentation. Such capabilities could dramatically accelerate cosmic discoveries, offering new insights into planetary formation, astrobiology, and fundamental physics.

The tourism sector might witness its most significant transformation yet. Imagine space travel becoming as accessible as international flights, creating unprecedented opportunities for civilian space experiences and educational missions. The societal implications of such accessibility could reshape our collective perspective on human spaceflight.

Advanced Earth observation networks also stand to benefit. More affordable satellite fleets could enable real-time environmental monitoring, precision agriculture systems, and rapid disaster response mechanisms with global coverage, addressing some of Earth's most pressing challenges.

Overcoming Terrestrial Constraints

Reducing Material Costs and Waste

Manufacturing in space presents unique advantages for minimizing resource consumption and production waste. Microgravity conditions allow novel fabrication techniques that use materials with greater efficiency - potentially reducing mass requirements by 30-40% for certain components. These savings become particularly significant for high-value medical components where material costs dominate production expenses. Eliminating terrestrial logistics chains further enhances the economic case for orbital production facilities.

Enhanced Precision and Control

The absence of gravitational distortion in space enables manufacturing precision unattainable on Earth. Without gravity-induced material sagging or settling, engineers can achieve atomic-scale alignment in critical components. This proves especially valuable for medical implants requiring perfect dimensional accuracy or optical systems demanding flawless surface finishes. The resulting quality improvements could reduce device failure rates by orders of magnitude in some applications.

Utilizing Unique Materials and Processes

Space's vacuum and microgravity enable material combinations impossible to create terrestrially. Certain metal alloys that separate under Earth's gravity mix uniformly in space, while biological materials can grow in three-dimensional structures without gravitational distortion. These capabilities open doors to revolutionary medical treatments, including organ scaffolds that mimic natural tissue architecture with unprecedented fidelity.

Addressing Terrestrial Resource Constraints

Orbital manufacturing could eventually utilize extraterrestrial resources, reducing dependence on Earth's finite material reserves. Initial concepts propose using lunar regolith or asteroid materials for construction, with some estimates suggesting certain rare elements might be more accessible in space than in terrestrial mines. This resource independence could prove crucial as demand grows for specialized medical materials.

Minimizing Contamination and Improving Sterility

The natural vacuum of space creates an ideal cleanroom environment superior to any Earth-based facility. Without atmospheric particles or microbial contamination, space-manufactured medical devices could achieve sterility levels 100-1000 times better than current standards. This proves particularly valuable for implants and surgical tools where infection risk remains a critical concern.