Additive manufacturing (AM), often called 3D printing, is a disruptive technology that's rapidly transforming industries across the globe. It's a process that creates three-dimensional objects from a digital design by adding material layer by layer. This contrasts significantly with traditional manufacturing methods, which often involve removing material. This fundamental difference unlocks a vast array of possibilities for product development and production.

The flexibility and customization capabilities of AM are unparalleled, allowing for intricate designs and complex geometries that were previously impossible to achieve with conventional methods. This opens doors for creating highly optimized and lightweight components, leading to significant advancements in various sectors.

Key Advantages of Additive Manufacturing

One of the most significant advantages of AM is its ability to create complex geometries. This translates to the potential for improved performance and reduced material usage. For example, parts can be designed with internal channels or support structures that would be difficult, if not impossible, to manufacture using traditional subtractive methods.

Another key benefit is the reduced need for tooling. AM significantly lowers the cost and time required for prototyping and production runs, particularly for small batches or customized parts. This agility is crucial in industries where rapid iteration and adaptation are paramount.

Applications Across Diverse Industries

Additive manufacturing is not limited to a specific industry. The diverse applications of AM span a wide range of sectors, including aerospace, automotive, medical, and consumer goods. In aerospace, AM is revolutionizing the design of aircraft components, enabling lighter, stronger, and more efficient structures. This, in turn, contributes to fuel savings and reduced environmental impact.

In the medical field, AM allows for the creation of customized implants and prosthetics, tailored to individual patient needs. This precision and personalization lead to improved patient outcomes and enhanced quality of life. The potential of AM to create intricate and personalized medical devices is profound.

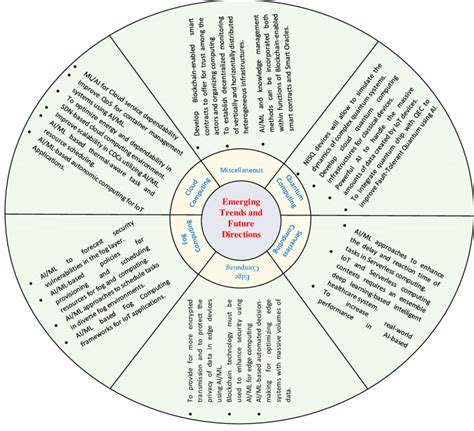

Future Trends and Innovations

The field of additive manufacturing is constantly evolving, with new materials, processes, and applications emerging all the time. Researchers are exploring new materials such as advanced polymers, metals, and composites, expanding the range of applications for AM. These advancements promise to further enhance the capabilities and efficiency of this transformative technology.

The integration of AM with other technologies, like artificial intelligence (AI) and machine learning (ML), is expected to play a crucial role in optimizing design and manufacturing processes in the future. These advancements will further streamline the AM workflow and allow for more efficient and cost-effective production.

Complex Geometries and Functional Integration

Complex Geometries in Additive Manufacturing

Additive manufacturing (AM), also known as 3D printing, offers unprecedented flexibility in designing and producing complex geometries. Traditionally, manufacturing processes were constrained by the limitations of subtractive methods, such as milling or machining. These limitations often dictated simple shapes and uniform structures. AM, however, allows for the creation of intricate, multi-faceted designs with internal cavities, complex support structures, and variable wall thicknesses, opening up a vast new world of possibilities for spacecraft components.

The ability to design parts with features that were previously impossible to manufacture using traditional methods is a key advantage. This translates directly into potentially more efficient and lighter spacecraft structures, leading to improved performance and reduced fuel consumption. Furthermore, AM allows for the creation of customized components that are precisely tailored to the specific needs of a mission, enhancing their functionality and reliability.

Functional Integration through AM

One of the most significant benefits of AM for spacecraft design is the potential for functional integration. Traditional spacecraft designs often required multiple components and assemblies to perform a single function. AM allows for the direct integration of multiple functionalities into a single, lightweight part. This can include the integration of cooling channels, sensors, actuators, and other critical systems directly within the structure of the component, leading to significant reductions in weight and complexity.

This integrated approach reduces the overall number of parts, resulting in fewer connections, joints, and interfaces. Fewer interfaces directly translate to fewer potential points of failure, thereby increasing the reliability and robustness of the spacecraft. This functional integration is a critical aspect of realizing the full potential of AM in aerospace applications.

Material Selection and Optimization

Choosing the appropriate materials for AM is crucial for spacecraft applications. Space environments present unique challenges, including extreme temperatures, radiation exposure, and the need for high strength-to-weight ratios. AM enables the use of a wider range of materials, including advanced alloys, composites, and even specialized ceramics, that might not be practical or feasible using traditional manufacturing methods. Carefully selecting and optimizing these materials is essential for ensuring the long-term performance and reliability of the spacecraft components.

Design Considerations for AM in Spacecraft

Specific design considerations must be taken into account when designing for AM. Factors such as part orientation, support structures, and layer resolution play a significant role in the final quality and performance of the printed component. Careful consideration of these factors during the design phase is critical to ensuring that the printed parts meet the stringent requirements of a space mission. This includes ensuring the structural integrity, thermal performance, and ability to withstand the harsh conditions of space.

Challenges and Future Directions

While AM offers remarkable advantages for spacecraft design, challenges remain. These include ensuring the repeatability and consistency of the manufacturing process, validating the long-term performance of AM-produced parts in the extreme conditions of space, and developing appropriate quality control and inspection procedures. Future research and development will focus on addressing these challenges and maximizing the potential of AM for creating innovative and robust spacecraft components.

Further research is also needed to explore new materials and manufacturing processes that can enhance the performance and capabilities of AM-produced parts. This includes developing advanced materials with optimized properties for specific space applications, and exploring new AM techniques that can produce larger and more complex components.

Mason jars, with their classic charm and reusable nature, are a fantastic option for storing grains. They offer a beautiful and practical way to organize your pantry, adding a touch of rustic elegance to your kitchen. Beyond the aesthetic appeal, their airtight seals ensure your grains remain fresh and protected from moisture, pests, and rodents, extending their shelf life significantly compared to open containers.

Material Selection and Future Applications

Material Selection Criteria for Optimal Performance

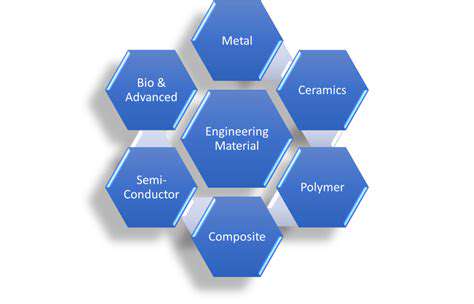

Choosing the right material is crucial for the success of any engineering project, and this selection process must consider a multitude of factors. Material properties, such as strength, stiffness, and ductility, directly impact the performance and reliability of the final product. Furthermore, factors like cost-effectiveness, availability, and environmental impact play a vital role in the decision-making process. Careful consideration of these elements is essential to ensure the selected material aligns with the specific requirements and constraints of the application.

A comprehensive evaluation of various material properties, including their behavior under different loading conditions, is essential. This analysis should also encompass the potential for degradation over time due to environmental factors or operational stresses. Considering the long-term performance of the material is paramount for ensuring the longevity and reliability of the final product.

Impact of Material Properties on Application Performance

The specific properties of a material significantly influence its suitability for a particular application. For instance, a material with high tensile strength might be ideal for structural components, while a material with excellent thermal conductivity might be preferred for heat exchangers. The interplay between material properties and the application's demands is a key consideration in material selection.

Understanding how the material will respond to different stresses and environmental conditions is critical. This includes factors like temperature fluctuations, corrosive environments, and cyclic loading. Accurate predictions of material behavior under these conditions are essential to prevent premature failure and ensure the desired lifespan of the product.

Sustainability Considerations in Material Selection

Environmental concerns are increasingly influencing material selection decisions. The sustainability of a material encompasses its entire lifecycle, from extraction and processing to disposal. Choosing materials with low environmental impact throughout their lifecycle is becoming a key factor in design decisions, and this includes considering the energy required for manufacturing and the potential for recycling or reuse.

The carbon footprint associated with material production and usage is a critical factor. Minimizing this footprint can help reduce the environmental impact of the product and contribute to a more sustainable future. This requires careful evaluation of the entire supply chain and the potential for alternative, more sustainable materials.

Emerging Materials and Technologies

Continuous advancements in materials science are leading to the development of novel materials with enhanced properties. These emerging materials often offer improved performance characteristics, such as higher strength-to-weight ratios, enhanced durability, or better thermal management. Exploring these new materials is vital for advancing technological capabilities.

Nanomaterials, composites, and bio-based materials are examples of emerging technologies that are pushing the boundaries of material science. These advancements can lead to significant improvements in performance and sustainability in various applications. Examining their potential is crucial for innovation and progress in the field.

Future Applications in Specific Industries

The selection of materials has a profound impact on the performance and efficiency of various industries, from aerospace to energy production. In aerospace, lightweight yet strong materials are crucial for reducing fuel consumption and improving flight efficiency. In energy production, materials with high thermal conductivity and resistance to corrosion are essential for optimal performance.

In the medical field, biocompatible materials are critical for developing implants and prosthetics, ensuring compatibility with the human body. The use of tailored materials can have a profound effect on the success and long-term functionality of medical devices.

Challenges and Opportunities in Material Selection

Material selection is a complex process, often involving trade-offs between various factors. Balancing performance requirements with cost constraints and sustainability goals is a critical aspect of the process. Finding innovative solutions to these challenges is essential for continued progress.

Developing new characterization techniques and modeling methods for materials is crucial for accurate predictions of material behavior under various conditions. These advancements can lead to more informed decisions and ultimately improve the performance of the final product.

Advanced Manufacturing Techniques and Material Properties

Advanced manufacturing techniques play a critical role in exploiting the full potential of new materials. 3D printing and additive manufacturing, for example, allow for the creation of complex geometries and intricate structures that are difficult or impossible to achieve with traditional manufacturing methods. This opens up opportunities for designing more efficient and specialized components.

The ability to tailor material properties through advanced processing techniques is transforming various industries. This approach allows engineers to optimize the material's properties to meet specific application demands, leading to significant improvements in performance and efficiency. This capability is vital for achieving breakthroughs in areas like energy storage, aerospace, and medical devices.