The real game-changers came from materials science. New heat-resistant alloys and composites finally gave us rockets that could take the punishment of re-entry and live to fly again. Meanwhile, our computers got smart enough to handle the insane calculations needed for precision landings, turning science fiction into reality.

The Private Sector Revolution

When SpaceX and Blue Origin entered the scene, everything changed. These private companies didn't just adopt reusable rockets - they perfected them, turning theoretical concepts into routine operations. Their success has slashed launch costs so dramatically that space is suddenly within reach for businesses and researchers who could only dream of it before.

This isn't just about joyrides for billionaires. Reusable rockets are the backbone of a new space economy, making satellite networks, orbital construction, and deep space exploration financially viable for the first time in history.

What Tomorrow Holds

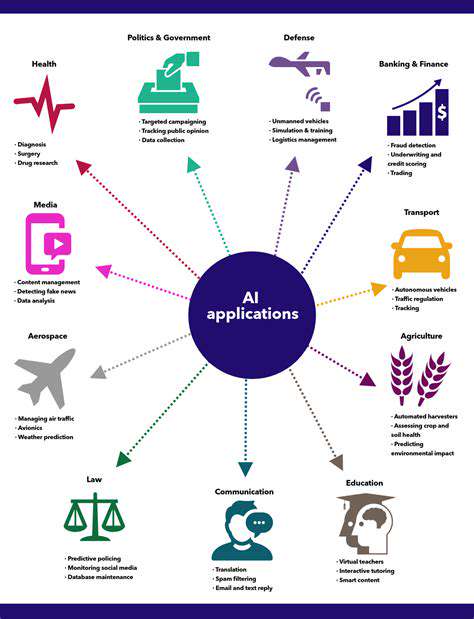

The next chapter in reusable rockets reads like a technophile's wishlist: engines that sip fuel instead of guzzling it, AI pilots that land rockets with superhuman precision, and materials that laugh at the heat of re-entry. We're not just tweaking the formula - we're reinventing space travel from the ground up.

As these technologies mature, we'll see launches become as routine as airline flights, opening the solar system to exploration and maybe even turning humanity into a multi-planet species. The final frontier just got a whole lot closer.

Challenges in Achieving Precise and Safe Landings

The Precision Paradox

Getting measurements right in rocket science isn't just about having fancy gadgets. It's a constant battle against a thousand tiny gremlins - temperature swings that warp your readings, electromagnetic fields that nudge your sensors, and even the act of measuring itself changing what you're trying to measure. Outsmarting these variables is half the job.

Precision isn't just about hitting the bullseye once; it's about grouping all your arrows tight, even if they're slightly off-center. That consistency matters more than absolute perfection when lives and billion-dollar rockets are on the line.

When Nature Fights Back

Rockets have to survive conditions that would vaporize most man-made objects. The atmosphere isn't just empty space - it's a seething mass of turbulence, temperature extremes, and electrical mayhem that can throw off even the best instruments. We've had to build special chambers just to test components, recreating the violence of space in our labs.

And the tools themselves? They're never perfect. Tiny calibration drifts, sensor quirks, and resolution limits all add up over time, like a game of telephone where the message gets slightly distorted with each repetition. Keeping everything in sync is a full-time job for teams of engineers.

Making Sense of the Chaos

Raw data from a rocket landing looks about as orderly as a toddler's finger painting. It takes serious number-crunching to spot the real patterns amid the noise. Modern statistical tools can tease out trends and flag anomalies that human eyes would miss entirely.

But the real magic happens when brains meet data. The best engineers don't just run the numbers - they understand the story behind them, knowing when a blip is just noise and when it's the first sign of catastrophe. That blend of technical skill and intuition is what separates successful landings from spectacular failures.

Innovative Technologies Enabling Reusable Landings

Supersonic Braking Systems

Modern retro-rockets are engineering marvels, capable of slamming the brakes on a descending rocket from orbital speeds. These aren't your grandfather's thruster packs - they're precision instruments that can adjust thrust a hundred times per second, dancing the rocket down to the pad with balletic grace.

The materials in these systems read like a sci-fi catalog: alloys that stay strong when glowing red-hot, ceramics that shrug off plasma temperatures, and composites lighter than aluminum but stronger than steel. Every ounce saved means more payload capacity and lower fuel bills.

The Brain Behind the Brawn

A rocket's guidance system is like a team of expert pilots, each monitoring different instruments and making micro-adjustments faster than human reflexes allow. Sensors feed data to hungry algorithms that predict the rocket's path dozens of steps ahead, compensating for wind shear, engine variations, and a dozen other variables in real-time.

This isn't just about following a pre-programmed path. The best systems actually learn from each landing, spotting patterns humans might miss and refining their approach with every flight. It's machine learning meets extreme engineering.

Materials That Defy Physics

The heat shield on a returning rocket faces temperatures hotter than lava, yet it has to survive multiple trips. Modern solutions borrow from nature (like the layered structure of abalone shells) and nanotechnology to create materials that dissipate heat while remaining feather-light.

Inside the rocket, 3D-printed components with microscopic cooling channels keep engines from melting, while smart composites sense stress and redistribute loads automatically. These aren't just materials - they're active participants in the landing process.

Virtual Testing Grounds

Before a single physical prototype is built, new rocket designs undergo thousands of simulated flights in supercomputers. These digital twins experience every conceivable failure mode - engine outs, sensor failures, freak weather - all in the safety of cyberspace.

The payoff? Problems get solved before they're problems, and each physical test becomes a verification rather than an experiment. It's reduced development time from years to months while making rockets exponentially more reliable.

The Economic Advantages of Reusable Rocket Technology

Bringing Down the Cost Ceiling

The financial impact of reusable rockets can't be overstated. Where traditional launches burned through hardware worth tens of millions per flight, reusable systems turn that into a rounding error. This seismic shift has made space accessible to universities, startups, and developing nations that previously couldn't dream of reaching orbit.

The savings compound with each flight. A Falcon 9 booster flying its 10th mission represents hundreds of millions in avoided costs compared to disposable alternatives. That's money that can fund more science, better technology, and bolder missions.

Launching on Demand

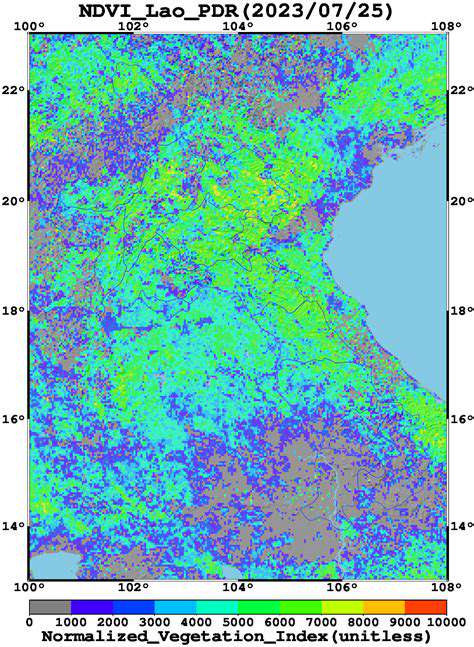

With reusable rockets, launch schedules have gone from cathedral-building timelines to something resembling an airline's flight board. Need a satellite replaced next month? Done. Have an urgent science mission? No problem. This responsiveness is revolutionizing industries from telecommunications to climate monitoring.

The effect is circular: more launches drive down costs further, which enables even more launches. We're witnessing the birth of a true space economy where access to orbit is limited only by imagination, not budgets.

Doing More With Less

Every kilogram saved in rocket construction translates directly to increased payload capacity. Reusable systems squeeze maximum performance from every gram, whether through optimized structures or engines that extract more thrust from each drop of fuel.

The results speak for themselves: missions that once required dedicated launches now fly as secondary payloads, and science packages grow more ambitious as transportation costs shrink. It's like upgrading from a economy car to a freight train while paying less for the privilege.

Greening the Final Frontier

While rockets will never be carbon-neutral, reusability dramatically reduces their environmental toll. Fewer rockets built means less mining, manufacturing, and testing. The Falcon 9's carbon footprint per kilogram to orbit is already orders of magnitude better than the Space Shuttle's was.

As the technology matures, we're seeing closed-loop systems where everything from fairings to second stages gets reused. It's not perfect, but it's light-years ahead of where we were just a decade ago.