Modern agriculture is evolving beyond traditional methods, embracing techniques that balance productivity with environmental stewardship. Farmers worldwide are discovering that nurturing soil ecosystems yields better long-term results than chemical-dependent approaches. This paradigm shift isn't just about preserving resources—it's about creating food systems that can withstand climate uncertainties.

Consider how traditional farms are transforming. They're adopting polyculture instead of monocrops, using natural pest predators rather than pesticides, and implementing water-saving irrigation systems. These innovations demonstrate that environmental responsibility and agricultural productivity aren't mutually exclusive—they're increasingly interdependent.

Renewable Energy Sources: Powering a Greener Future

The energy landscape is undergoing its most significant transformation since the Industrial Revolution. Solar panel efficiencies have improved dramatically, while offshore wind farms now harness stronger, more consistent breezes. Even hydropower is seeing innovations with smaller, less ecologically disruptive turbine designs.

What's particularly exciting is how these technologies are becoming more accessible. Community solar projects allow neighborhoods to share renewable benefits, while microgrid technologies empower remote areas. This democratization of energy production could redefine global power dynamics within our lifetime.

Waste Management and Recycling Initiatives: Minimizing Environmental Impact

Modern waste solutions look beyond simple disposal. Advanced sorting facilities use AI-powered optical scanners to achieve unprecedented recycling accuracy. Meanwhile, innovative companies are finding ways to repurpose previously non-recyclable materials into construction supplies and consumer products.

The most promising development might be the circular economy concept, where product designers consider end-of-life disposal from the initial design phase. This approach could eventually make landfills obsolete, turning waste streams into resource pipelines.

Sustainable Transportation: Moving Towards a Low-Carbon Future

Urban planners are reimagining cityscapes with mobility in mind. Bike-sharing systems have become smarter with GPS tracking, while electric buses now feature rapid-charging capabilities at stops. Even parking infrastructure is evolving, with dynamic pricing algorithms reducing unnecessary congestion.

The real game-changer? Autonomous electric vehicles that can be summoned like taxis but operate with ride-sharing efficiency. When combined with improved public transit, this could reduce urban vehicle numbers by 75% while maintaining accessibility.

Conservation and Biodiversity: Protecting Our Natural Resources

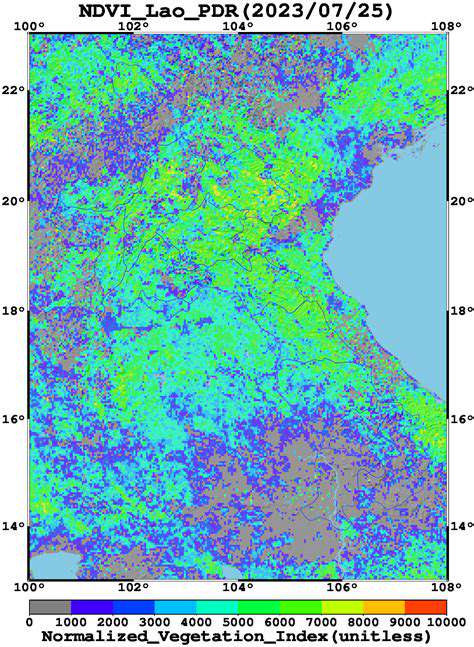

Modern conservation goes beyond setting aside protected areas. Scientists now use environmental DNA sampling to monitor ecosystem health, while satellite imagery tracks deforestation in real-time. There's growing recognition that indigenous land management practices often outperform modern conservation methods in maintaining biodiversity.

Perhaps most importantly, habitat corridors are being established to allow species migration in response to climate change. This proactive approach acknowledges that static reserves won't suffice in our rapidly warming world.

Sustainable Consumption and Production Patterns: Reducing Our Footprint

The sharing economy has demonstrated that access can replace ownership for many products. From tool libraries to clothing rental services, consumers are embracing models that maximize resource utilization. Food delivery apps now highlight local producers, reducing transportation emissions while supporting regional economies.

Digital product passports—QR codes detailing a product's environmental impact—are empowering consumers to make informed choices. This transparency could drive manufacturers toward cleaner production methods.

Sustainable Urban Planning: Creating Resilient Communities

Cities are becoming laboratories for sustainable innovation. Green roofs now double as urban farms, while permeable pavements reduce stormwater runoff. District energy systems use waste heat from buildings to warm nearby homes, achieving efficiencies impossible with individual units.

The most transformative development might be 15-minute city planning, where daily needs are accessible within a short walk or bike ride. This approach not only reduces emissions but also fosters stronger community connections and improves public health.

The Impact of Digitalization on Design and Production

The Rise of Digital Twins in Aerospace Design

Virtual prototyping has reached new heights with digital twin technology. These dynamic models don't just simulate static conditions—they evolve in real-time, incorporating flight data from thousands of sensors. Engineers can now predict wear patterns years in advance, optimizing maintenance schedules with unprecedented precision.

The implications extend beyond maintenance. Digital twins enable what-if scenario testing that would be prohibitively expensive or dangerous with physical prototypes. This capability is revolutionizing how we approach complex system design across multiple industries.

Enhanced Collaboration and Communication Through Digital Platforms

Cloud-based design platforms have erased geographical barriers in engineering. Teams spread across continents can now work on the same 3D model simultaneously, with change histories meticulously tracked. Augmented reality tools allow engineers to visualize modifications in real-world contexts before implementation.

This collaborative environment has spawned new workflows. Version control systems have become so sophisticated that they can predict potential conflicts between design changes, suggesting resolutions before problems arise.

Automation and Robotics in Manufacturing Processes

Robotic systems have achieved remarkable dexterity. Modern collaborative robots (cobots) work safely alongside humans, combining machine precision with human judgment. In aerospace manufacturing, robotic arms equipped with advanced sensors can detect microscopic surface imperfections invisible to the human eye.

The newest frontier is self-programming robotics. Machine learning algorithms enable robots to optimize their own movements through trial and error, finding more efficient paths and grips without explicit programming.

Data-Driven Design Optimization and Material Selection

Generative design software has transformed the creative process. Engineers input performance requirements and let algorithms explore thousands of potential solutions. The results often include organic, lightweight structures that human designers might never conceive.

Material science has similarly benefited from data analytics. Computational materials discovery can predict the properties of hypothetical alloys, accelerating the development of new composites with tailored characteristics.

Improved Quality Control and Reduced Defects

Computer vision systems now inspect products with superhuman accuracy, detecting flaws at microscopic scales. Thermal imaging can identify stress points in assemblies before they become failures. Even sound analysis is being used—acoustic sensors can detect abnormal vibrations signaling potential issues.

Perhaps most impressive is how these systems learn. Each detected defect improves the algorithm's ability to spot similar issues in the future, creating a virtuous cycle of quality improvement.

Sustainable Manufacturing Practices via Digitalization

Digital tools enable precision manufacturing that minimizes waste. Laser cutting guided by AI can optimize material layouts, while 3D printing builds components layer by layer with near-zero scrap. Energy management systems dynamically adjust factory power consumption based on real-time pricing and availability.

The marriage of digital and sustainable manufacturing is yielding unexpected benefits. For instance, some aerospace manufacturers now use recycled metal powders for additive manufacturing, closing material loops that were previously linear.

Predictive Maintenance and Enhanced Safety

The latest predictive maintenance systems don't just alert technicians to impending failures—they can diagnose the root cause. Vibration analysis combined with machine learning can distinguish between dozens of potential fault conditions. Some systems even recommend specific repair procedures based on historical success rates.

This technology is preventing accidents before they occur. By analyzing subtle changes in multiple sensor streams, these systems can detect anomalies that would escape human notice until catastrophic failure occurs.

The content creation landscape is undergoing a quiet revolution. Emerging tools are augmenting human creativity rather than replacing it, offering intelligent suggestions that spark new ideas. This collaborative approach between human and artificial intelligence is producing content that's both highly personalized and deeply resonant.

The Role of Automation and Robotics in Aerospace Manufacturing

Automation in Manufacturing

The modern factory floor barely resembles its twentieth-century predecessor. Automated guided vehicles (AGVs) navigate dynamic environments using LiDAR, while robotic arms equipped with force feedback can assemble delicate components with a jeweler's precision. This harmonious integration of systems creates manufacturing ecosystems that are both highly efficient and remarkably adaptable.

What's particularly noteworthy is how these systems learn from experience. Machine vision systems that once required painstaking calibration now train themselves using synthetic data, achieving near-perfect accuracy within hours rather than weeks.

Robotic Process Automation (RPA)

RPA has evolved beyond simple task automation. Modern systems can handle semi-structured data, make context-aware decisions, and even adapt to minor process changes. In aerospace manufacturing, RPA bots coordinate between ERP systems, supply chain databases, and production scheduling tools, ensuring perfect synchronization.

The newest generation of RPA incorporates natural language processing, allowing it to interpret emails, extract relevant data, and take appropriate actions—all without predefined rules for every possible scenario.

The Impact on Jobs

While automation displaces some traditional roles, it's creating demand for new hybrid skills. The most sought-after workers today are those who understand both manufacturing processes and the digital systems that control them. Community colleges and vocational programs are responding with curricula that blend mechanical skills with data literacy.

This transition represents not job elimination but job transformation. The workers who embrace continuous learning are finding themselves more valuable than ever in the automated workplace.

Maintenance and Repair of Automated Systems

Predictive maintenance has become extraordinarily sophisticated. Vibration sensors can detect bearing wear months before failure, while thermal imaging identifies electrical issues invisible to the naked eye. Augmented reality guides technicians through complex repairs, overlaying schematics and torque specifications directly onto equipment.

The most advanced systems employ digital twins for troubleshooting. Technicians can test repair procedures in virtual environments before applying them to physical equipment, reducing downtime and improving first-time fix rates.

The Future of Automation

Next-generation automation will be anticipatory rather than reactive. Systems will predict production bottlenecks before they occur and dynamically reallocate resources. Self-optimizing assembly lines will continuously tweak their own parameters for maximum efficiency. Even quality control will become proactive, with real-time process adjustments preventing defects rather than detecting them.

This shift from programmed automation to autonomous optimization represents the next great leap in manufacturing intelligence.

Ethical Considerations

As automation becomes more autonomous, accountability questions grow more complex. Who's responsible when an AI-driven system makes a harmful decision? How do we ensure algorithms don't inadvertently discriminate? These challenges require multidisciplinary solutions combining technical, legal, and philosophical expertise.

The most pressing ethical imperative is ensuring automation benefits all stakeholders, not just those who can afford the technology. This may require new models of technology access and workforce transition support.

Cost-Benefit Analysis

Modern ROI calculations for automation must consider factors beyond direct labor savings. The ability to rapidly reconfigure production lines for new products, the reduction in quality-related recalls, and the competitive advantage of faster time-to-market all factor into the equation. Cloud-based automation platforms are also reducing upfront costs, making advanced capabilities accessible to smaller manufacturers.

The most forward-thinking companies now evaluate automation investments through the lens of strategic flexibility—the ability to adapt to unforeseen market changes that haven't yet materialized.