AI-driven predictive maintenance is revolutionizing industrial practices. This approach supersedes traditional reactive maintenance that addresses problems after they emerge. Instead, AI-based predictive systems forecast potential equipment issues, enabling preventative measures that dramatically decrease operational interruptions.

Through analysis of extensive data from multiple sources, AI systems can recognize patterns and irregularities signaling upcoming equipment failures. This capability allows organizations to plan maintenance well ahead of time, reducing expensive disruptions and extending equipment service life.

Data Collection and Analysis: The Foundation of AI-Powered Predictive Maintenance

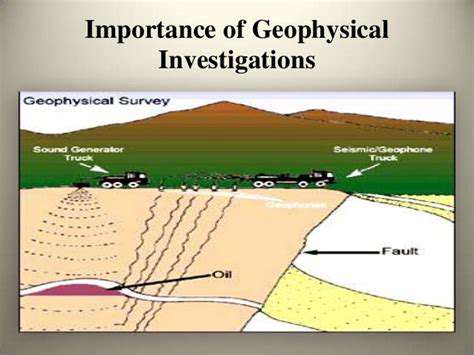

The cornerstone of AI-based predictive maintenance lies in data gathering and examination. This includes sensor measurements, operational metrics, and historical maintenance documentation. The precision and thoroughness of this information are critical for the predictive system's effectiveness.

Advanced algorithms process this data to detect abnormalities and forecast potential malfunctions. This analysis depends on reliable data channels to maintain information accuracy and timeliness for predictive modeling.

AI Algorithms for Failure Prediction

Various AI techniques, including machine learning models such as neural networks, support vector machines, and deep learning structures, are employed for failure prediction. These systems learn from past data to identify correlations and patterns that can predict upcoming failures with considerable accuracy.

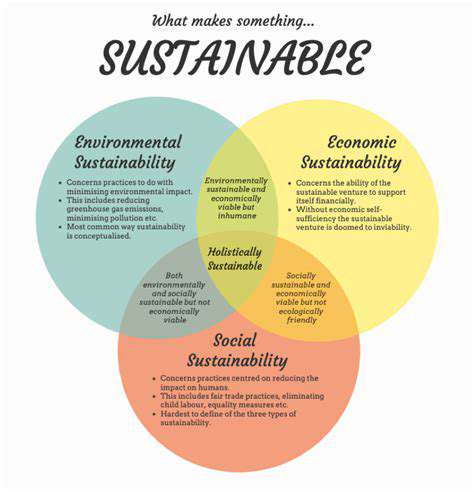

Benefits of Predictive Maintenance

Implementing AI-driven predictive maintenance offers numerous advantages. Significant reductions in operational downtime lead to major cost savings and productivity gains. Additionally, predictive maintenance boosts operational effectiveness and enhances safety protocols by preventing sudden equipment breakdowns.

Predictive systems also allow for optimized maintenance scheduling, better resource distribution, and decreased overall maintenance expenditures.

Implementation Considerations and Challenges

Deploying AI-powered predictive maintenance requires careful evaluation of multiple factors, including data infrastructure, algorithm choice, and technical expertise. Incorporating AI into current maintenance routines can present difficulties, necessitating mindset changes and personnel training.

Data protection and confidentiality are also important concerns, as these systems often manage sensitive operational information. Addressing these issues is essential for successful implementation and long-term benefits.

Future Trends in AI-Powered Predictive Maintenance

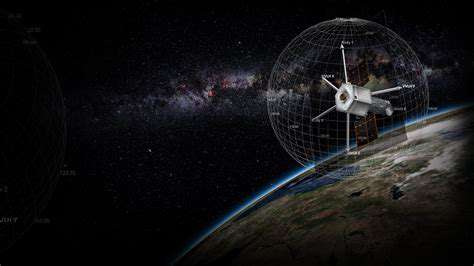

The field of AI-based predictive maintenance continues to advance. Developing trends include IoT device integration, sophisticated analytical methods, and more advanced AI models. These innovations promise improved accuracy and efficiency in predicting equipment issues and refining maintenance approaches.

Future developments will likely concentrate on real-time analysis and automated decision processes, leading to more proactive and responsive maintenance operations.

Advanced Anomaly Detection and Fault Diagnosis

Advanced Anomaly Detection Techniques in Aerospace Data

Sophisticated anomaly detection methods are essential for aerospace system safety and dependability. These techniques surpass basic statistical approaches by incorporating machine learning algorithms that can identify subtle behavioral deviations traditional methods might overlook. Early anomaly detection enables preventative maintenance and avoids serious failures by catching issues early in the system lifecycle, potentially saving substantial costs and preventing incidents. Processing extensive data from various sensors, including engine metrics, structural condition, and environmental factors, is crucial for this process. This thorough analytical method is particularly important in the aerospace industry where safety and reliability are critical.

Various anomaly detection approaches, including clustering, outlier identification, and neural networks, are used to spot patterns indicating potential issues. These algorithms train on historical data to establish normal performance benchmarks and detect variations that may signal problems. The specific algorithm choice depends on data characteristics and the type of anomalies being sought. For example, data showing gradual performance decline might require time-series analysis rather than methods focusing on isolated outliers.

Fault Diagnosis Using AI in Aerospace

AI plays a crucial role in fault diagnosis by analyzing complex data streams from multiple sources. This involves using advanced algorithms to interpret sensor outputs, flight records, and other relevant data to determine malfunction causes. By leveraging AI's pattern recognition capabilities, engineers can diagnose issues faster and more accurately than with conventional methods. This leads to quicker problem resolution, reduced downtime, and safer aircraft operation.

Effective fault diagnosis is vital for aerospace system maintenance and operation. AI-powered diagnostic tools can process sensor data in real-time, identifying potential problems before they escalate. This proactive method is essential for maintaining operational efficiency and avoiding expensive repairs or replacements.

Machine Learning Models for Anomaly Detection

Machine learning techniques, including support vector machines (SVMs), decision trees, and artificial neural networks, are increasingly applied in anomaly detection. These models learn from historical data to establish normal behavior profiles, enabling them to spot deviations and flag potential anomalies. Model selection depends on data characteristics and required accuracy levels. Neural networks, for instance, excel at identifying complex patterns in high-dimensional data, making them suitable for tasks like engine performance prediction or structural damage detection.

These models train on comprehensive datasets to recognize subtle patterns and variations indicating anomalies. This requires careful data preparation and feature engineering to ensure the model trains on relevant, informative data. Model performance is critical, as incorrect anomaly identification can lead to unnecessary interventions or failure to detect serious issues.

Data Preprocessing and Feature Engineering

Effective anomaly detection depends heavily on proper data preparation and feature development. Raw aerospace system data often contains noise, missing values, and inconsistencies. Preparation steps like cleaning, transformation, and normalization are essential to ensure analysis quality and reliability. Feature development involves selecting and creating new elements that best represent underlying data patterns and relationships. These techniques are crucial for improving anomaly detection model accuracy and efficiency.

Appropriate feature selection and development are key to successful aerospace anomaly detection. Feature choices significantly impact model ability to accurately identify anomalies. By creating informative features capturing essential data aspects, prediction accuracy and overall process efficiency improve.

Real-Time Anomaly Detection and Response

Immediate anomaly detection is vital for proactive maintenance and aerospace safety. By continuously monitoring data streams from various sources, systems can identify anomalies as they occur, enabling immediate responses to mitigate risks. This capability is critical for ensuring aircraft and spacecraft safety and reliability during operation. The speed and precision of real-time anomaly detection are essential for preventing potential catastrophic failures and maintaining optimal performance.

Integration with Existing Aerospace Systems

Incorporating advanced anomaly detection and fault diagnosis systems into current aerospace infrastructure is critical for smooth implementation and effective use. This requires careful consideration of data interfaces, communication protocols, and system architectures. Seamless integration with existing infrastructure is vital for maintaining operational continuity and ensuring efficient data flow. Furthermore, integration must be designed to minimize disruption to existing workflows and procedures.

Few culinary creations match the comforting warmth of homemade creamy tomato soup. Canned diced tomatoes serve as the foundation, providing rich, concentrated tomato flavor that's difficult to surpass. A touch of cream or milk transforms the texture into something truly luxurious, while fresh basil leaves add aromatic freshness that enhances the overall taste. Proper seasoning is essential—just the right balance of salt and pepper brings all components into perfect alignment. The preparation method remains straightforward: simmer until tomatoes soften, then blend to silky smoothness. This approach ensures consistent, excellent results on every attempt.

Optimizing Flight Operations and Fuel Efficiency with AI

Improving Fuel Efficiency

Fuel expenditures constitute a major portion of airline operational costs. Enhancing flight operations to reduce fuel consumption is essential for financial viability. This involves detailed route planning, considering elements like wind conditions, altitude changes, and air traffic density. Implementing sophisticated flight planning software and utilizing current weather information can substantially decrease fuel usage. Careful management of aircraft weight distribution can further improve fuel economy.

Specific approaches, such as optimizing climb and descent patterns, and using more efficient cruising speeds, are crucial for achieving meaningful fuel savings. Modern aircraft feature advanced engines and systems, but realizing their full potential requires skilled pilots and operational procedures that maximize efficiency.

Enhancing Safety Procedures

Flight safety remains the highest priority. Comprehensive training programs for pilots and crew members are essential to ensure competence in handling various emergency scenarios. This includes regular simulator sessions, scenario-based exercises, and ongoing performance assessments. Thorough pre-flight inspections and maintenance procedures are critical for identifying and addressing potential risks before departure. Detailed safety audits and reviews are necessary to maintain stringent safety standards.

Implementing advanced safety technologies, such as improved weather radar systems and enhanced communication networks, will further strengthen safety measures. Regular safety briefings and established communication protocols ensure all crew members remain current with the latest safety procedures.

Streamlining Air Traffic Management

Efficient air traffic control is crucial for minimizing delays and ensuring smooth operations. Optimizing flight routes and schedules can significantly reduce congestion around airports and in airspace. Real-time data analysis and predictive modeling can help anticipate potential bottlenecks and adjust flight paths accordingly. This requires cooperation between air traffic controllers and airlines.

Implementing advanced air traffic control systems, including sophisticated software and automated route management, can substantially decrease delays and improve overall efficiency.

Maintaining Aircraft Condition

Keeping aircraft in optimal condition is essential for safety and operational effectiveness. Regular inspections, maintenance, and repairs are necessary to prevent mechanical failures and ensure aircraft longevity. Implementing proactive maintenance schedules, rather than reactive ones, can significantly reduce the risk of unexpected in-flight malfunctions. This includes strict adherence to manufacturer guidelines and using advanced diagnostic equipment.

Proper storage and handling of spare parts and maintenance supplies are essential for smooth maintenance operations. A well-maintained fleet ensures reliability and reduces potential downtime.

Improving Crew Productivity and Morale

A motivated and well-rested crew is essential for efficient and safe flight operations. Creating a supportive work environment for flight crews improves morale. This includes providing adequate rest periods between flights and preventing overwork. Offering competitive compensation and benefits packages helps attract and retain skilled personnel. Comprehensive training programs, including stress management and communication skills, are also necessary for crew well-being.

Investing in crew welfare initiatives, such as flexible scheduling and accessible support services, can enhance productivity and reduce burnout. Prioritizing crew well-being isn't just an HR concern—it directly impacts safety and operational efficiency.