Introduction to Aerodynamic Drag

Understanding the Concept of Drag

Aerodynamic drag is a crucial factor impacting the performance and efficiency of aircraft. It's the resistance an object, in this case, an aircraft, experiences when moving through the air. This resistance arises from various forces, primarily the pressure difference between the front and rear surfaces of the aircraft and the friction between the air molecules and the aircraft's surface. Understanding this fundamental concept is paramount to designing and operating aircraft that achieve optimal performance with minimal energy expenditure.

Different types of drag contribute to the overall resistance, each with its own characteristics and influencing factors. This necessitates a comprehensive understanding of each component to effectively mitigate drag and enhance overall aircraft efficiency. This knowledge is essential for engineers and pilots alike to maximize flight range and minimize fuel consumption.

Types of Aerodynamic Drag

Several types of drag contribute to the overall aerodynamic resistance experienced by an aircraft. Pressure drag, often associated with blunt shapes, arises from the pressure differences on the surfaces of the aircraft. Skin friction drag, on the other hand, is a result of the friction between the air and the aircraft's surface. Induced drag, a consequence of generating lift, is also significant and directly related to the wing's design and the aircraft's angle of attack. These different types of drag need to be carefully considered and minimized during the design and operation of aircraft to achieve optimal performance.

The Impact of Drag on Aircraft Performance

Aerodynamic drag directly translates into increased fuel consumption. Higher drag forces require more thrust to maintain a given speed, leading to a greater demand for power and, consequently, a higher fuel burn. This impact is especially pronounced at higher speeds, as the drag force increases with the square of the velocity. Consequently, minimizing drag becomes a paramount concern for achieving better fuel efficiency and extending flight range, crucial factors in modern aviation.

Understanding the relationship between drag and aircraft performance is fundamental to optimizing flight characteristics. By reducing drag, aircraft can achieve higher speeds with less power and better fuel efficiency, leading to significant cost savings and improved environmental sustainability.

Drag Reduction Techniques

Various techniques are employed to reduce aerodynamic drag, each targeting specific components of the overall drag force. Streamlining the aircraft's shape, reducing the frontal area, and using advanced materials with low skin friction coefficients are crucial steps in this process. Employing winglets or other specialized wing designs can significantly reduce induced drag, further improving the aircraft's performance characteristics.

Future Trends in Drag Reduction

Ongoing research and development in the field of aerodynamics are constantly pushing the boundaries of drag reduction techniques. Advanced computational fluid dynamics (CFD) simulations are playing a critical role in optimizing aircraft designs for reduced drag. New materials and manufacturing processes are being explored to achieve lower skin friction coefficients, further enhancing fuel efficiency. Sustainable aviation fuels and innovative propulsion systems are also crucial aspects of achieving the ultimate goal of reduced drag and environmental responsibility.

Innovative Surface Treatments and Coatings

Enhanced Durability

Innovative surface treatments are revolutionizing the way we approach product durability. These treatments, often employing advanced materials science, significantly increase a material's resistance to wear, tear, and corrosion. This enhanced durability translates to a longer lifespan for products, ultimately reducing waste and promoting sustainability.

By altering the surface microstructure, these treatments create a barrier against environmental degradation. This barrier effect effectively shields the underlying material from harsh conditions, protecting it from damage and extending its useful life.

Improved Aesthetics

Beyond enhanced durability, innovative surface treatments also significantly impact the aesthetic appeal of products. Sophisticated techniques can create a wide range of finishes, from lustrous metallic reflections to matte, textured surfaces. This allows for a greater degree of customization and design flexibility, enabling manufacturers to cater to diverse consumer preferences.

These treatments offer a palette of possibilities for achieving unique and visually appealing finishes, pushing the boundaries of design.

Cost-Effectiveness

Contrary to initial assumptions, many innovative surface treatments can be surprisingly cost-effective in the long run. While the initial investment might be slightly higher compared to traditional methods, the extended lifespan of the treated product often offsets the cost. Reduced maintenance requirements and the avoidance of premature replacements contribute to a lower total cost of ownership.

The long-term savings offered by these treatments make them a worthwhile investment for businesses seeking sustainable solutions. Minimized waste and extended product lifecycles contribute to a more financially viable and environmentally conscious approach.

Sustainable Practices

Surface treatments are increasingly aligned with sustainable practices. Many new technologies employ eco-friendly materials and processes, minimizing the environmental impact of manufacturing. These sustainable choices contribute to a reduced carbon footprint and promote a more responsible approach to production.

The use of recycled materials or bio-based components in these treatments is a significant step towards environmentally conscious manufacturing. Promoting these innovative solutions is crucial for a more sustainable future.

Advanced Functionality

Certain surface treatments can imbue products with enhanced functionalities. These can include improved electrical conductivity, enhanced thermal resistance, or enhanced biocompatibility. Such functionalities open up a wide range of applications in diverse industries, from electronics to medical devices.

These advanced functionalities enable the creation of more sophisticated and high-performance products. This allows for the development of innovative solutions across various industries, driving advancements in technology and design.

Enhanced Safety and Health

Surface treatments can be crucial in ensuring the safety and health of consumers. For instance, treatments can make materials less prone to bacterial growth or improve resistance to chemical hazards. This is particularly important in medical devices, food packaging, and consumer products.

Specific treatments can inhibit the growth of harmful microorganisms, enhancing the safety of products. This is a crucial aspect of modern manufacturing, ensuring consumer well-being and product safety.

The Role of Advanced Materials

Advanced Materials in Electronics

Advanced materials play a crucial role in the development of modern electronics, enabling the creation of smaller, faster, and more efficient devices. Semiconductors, like silicon and gallium nitride, are fundamental to integrated circuits and transistors, enabling the processing power of computers and smartphones. These materials possess unique electrical properties, allowing them to control the flow of electrons and perform complex calculations. Their continued advancement is essential for the future of electronics.

Applications in Energy Technologies

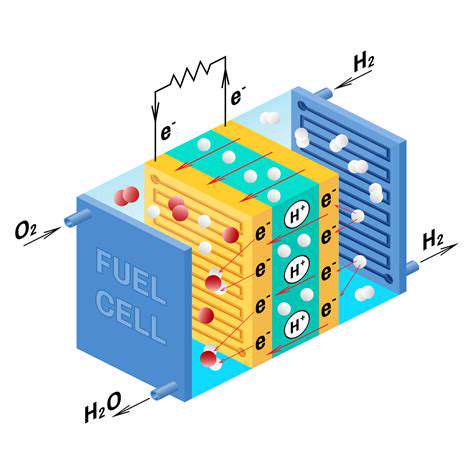

The demand for sustainable energy solutions has spurred research and development in advanced materials for energy storage and conversion. Materials like lithium-ion batteries and solid-state batteries are critical for electric vehicles and renewable energy systems. These materials must exhibit high energy density, long lifespan, and safety to meet the growing need for efficient and reliable energy storage solutions. Further research into new materials promises to revolutionize energy storage and generation technologies.

Biomedical Applications and Technologies

Advanced materials are transforming the biomedical field, offering innovative solutions for diagnostics, treatments, and prosthetics. Biocompatible materials, such as polymers and metals, are used to create implants and scaffolds for tissue regeneration. These materials must be compatible with the human body, avoiding harmful immune responses and promoting tissue integration. Their use in drug delivery systems also holds great promise, enabling targeted therapies and improved treatment outcomes.

Structural Materials and Engineering

Advanced materials are improving the performance and efficiency of structural elements in various engineering applications. Lightweight yet strong materials, like carbon fiber composites and advanced alloys, are increasingly used in aerospace and automotive industries. These materials contribute to reduced weight, improved fuel efficiency, and enhanced safety features. Their superior mechanical properties and reduced environmental impact are significant advantages in modern engineering design.

Environmental Remediation and Sustainability

The environmental challenges of our time necessitate the development of advanced materials for remediation and sustainability. Materials with enhanced adsorption capabilities are being explored for removing pollutants from water and air. These materials are also being developed to capture and store carbon dioxide emissions, potentially mitigating the effects of climate change. The creation of sustainable materials is a critical step towards a more environmentally conscious future.

Manufacturing and Processing Innovations

Advanced materials require sophisticated manufacturing and processing techniques. Innovative approaches to material synthesis, including 3D printing and nanomanufacturing, are enabling the creation of complex structures and functional materials. These techniques offer precise control over material properties and allow for the customization of structures to meet specific requirements. Further advancements in these fields will unlock new possibilities for the development and application of advanced materials.

Future Trends and Research in Drag Reduction

Computational Fluid Dynamics (CFD) Advancements

The field of computational fluid dynamics (CFD) is rapidly evolving, offering powerful tools for predicting and optimizing aerodynamic performance. Sophisticated CFD simulations are becoming increasingly accessible, enabling researchers to explore complex flow phenomena around complex geometries with unprecedented detail. This allows for the investigation of a wider range of drag reduction strategies, including the evaluation of novel surface textures, active flow control methods, and the impact of varying flow conditions. Furthermore, advancements in meshing techniques and turbulence modeling are leading to more accurate and reliable predictions, enabling engineers to make informed design choices and potentially accelerate the development of drag-reducing technologies.

CFD simulations are no longer limited to simple shapes. Researchers are now able to model the intricate flow patterns around intricate aircraft wings, car bodies, and even wind turbine blades, providing detailed insights into the drag-inducing mechanisms. This detailed understanding allows for the targeted design of surfaces and components that minimize drag, leading to significant performance gains and fuel efficiency improvements.

Active Flow Control Strategies

Active flow control methods hold significant promise for reducing aerodynamic drag. These techniques involve manipulating the flow field around an object using external forces, such as blowing or suction, to alter the flow structure and reduce separation. Research is focusing on the development of more efficient and controllable actuators, enabling precise manipulation of the boundary layer and delaying or eliminating separation bubbles. This approach is especially relevant for complex geometries where passive methods may prove insufficient.

A key aspect of active flow control research is the development of feedback control systems. These systems use sensors to monitor the flow field in real-time and adjust the actuators accordingly, allowing for dynamic adaptation to changing conditions. This adaptive capability is critical for optimizing drag reduction in various flight regimes and environmental conditions. The potential benefits of these approaches are substantial, potentially leading to significant reductions in fuel consumption and increased efficiency in a variety of applications.

Material Science Innovations

Advances in material science are paving the way for the development of new, drag-reducing surfaces. Researchers are exploring novel materials with unique surface textures, nanoscale structures, and tailored properties to reduce friction and minimize turbulence. These materials may incorporate self-healing properties, allowing for surface repair and maintaining optimal performance over extended periods. This is particularly important for applications subjected to harsh environmental conditions or high-speed travel.

Bio-Inspired Design Principles

Nature provides numerous examples of efficient aerodynamic designs. Bio-inspired design principles are increasingly being incorporated into aerodynamic research, drawing inspiration from the streamlined shapes and surface textures of animals and plants. This approach focuses on mimicking the natural mechanisms for reducing drag, such as the laminar flow characteristics found on the bodies of certain fish and birds. The application of bio-mimicry to aerodynamic design can lead to the development of novel solutions for drag reduction, promoting a more sustainable and efficient approach to engineering.

Sustainable Drag Reduction Strategies

The pursuit of drag reduction is intrinsically linked to sustainability goals. Research is increasingly focusing on developing sustainable materials and techniques that not only reduce drag but also minimize environmental impact. This includes exploring bio-based polymers, recycled materials, and manufacturing processes that are environmentally friendly. A focus on reducing the overall energy consumption associated with transportation and industrial applications is essential for a sustainable approach to drag reduction. Such strategies are crucial for the development of more environmentally friendly and efficient technologies.