The Rise of Advanced Composites in Aircraft Construction

The Fundamental Properties of Advanced Composites

Advanced composites, a class of materials combining high strength and low weight, are revolutionizing aircraft construction. These materials, typically comprising a strong, lightweight fiber (like carbon fiber or aramid) embedded in a polymer matrix, offer exceptional mechanical properties. Their inherent strength-to-weight ratio is significantly superior to traditional metallic alloys, leading to substantial reductions in aircraft weight, and thus, fuel consumption and emissions.

The unique structural characteristics of these composites contribute to increased stiffness and durability, allowing for more efficient designs and potentially safer aircraft operation. Understanding the specific properties of these materials, including their modulus of elasticity, tensile strength, and impact resistance, is crucial to realizing their full potential within aerospace applications.

Design Considerations for Composite Integration

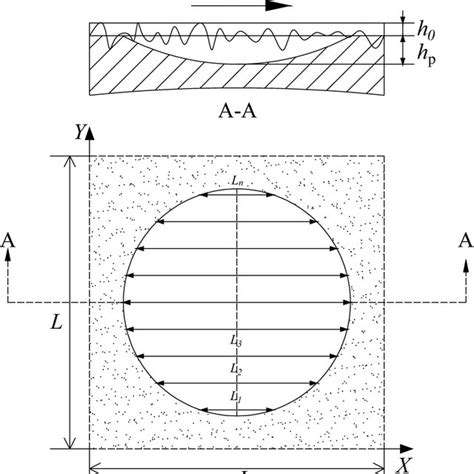

Designing with advanced composites necessitates a shift in approach compared to traditional metal-based aircraft. Engineers must consider the unique properties of these materials, such as their anisotropic nature (different properties in different directions). This anisotropy requires meticulous design considerations, including the precise orientation and layering of the composite fibers to achieve optimal structural performance. Furthermore, the manufacturing processes for composites often differ from those used for metal alloys, requiring careful consideration of tooling and assembly techniques.

Moreover, the design process must account for the potential for damage accumulation and failure mechanisms specific to composite materials. The interplay between design, manufacturing, and material selection is critical to achieving a robust and reliable aircraft structure.

Manufacturing Processes for Composite Components

The manufacturing of advanced composite components involves a range of techniques, each with its own advantages and limitations. Techniques like filament winding, prepreg layup, and resin transfer molding (RTM) are commonly used to create complex shapes and structures from composite materials. Each method has unique implications for material properties, production costs, and the overall design flexibility of the aircraft structure.

Careful attention to detail in the manufacturing process is essential to ensure the quality and integrity of the final composite component. Maintaining precise control over factors like fiber orientation, resin content, and curing conditions is critical to achieving the desired mechanical properties and preventing defects.

Cost-Effectiveness and Sustainability

While advanced composites have traditionally been perceived as more expensive than traditional metals, ongoing research and development are driving down costs and enhancing manufacturing efficiency. The long-term cost savings associated with reduced fuel consumption and maintenance requirements are increasingly significant factors in the economic viability of composite aircraft. This cost reduction is coupled with the environmental benefits, as composite aircraft contribute to reduced carbon emissions and a more sustainable future for air travel.

The adoption of advanced composites is therefore not only a technological advancement but also a crucial step towards a more environmentally conscious and economically efficient aerospace industry.

Impact on Aircraft Performance and Efficiency

The incorporation of advanced composites into aircraft construction results in significant improvements in performance and efficiency. Reduced weight translates directly to lower fuel consumption, leading to decreased operating costs and a smaller environmental footprint. Improved strength-to-weight ratios allow for the design of more aerodynamic aircraft configurations, further enhancing fuel efficiency and performance. These advancements are critical to the long-term viability and sustainability of air travel.

Future Trends and Applications

The future of advanced composites in aircraft construction is bright, with ongoing research and development pushing the boundaries of material science and engineering. The exploration of new fiber types, matrix materials, and manufacturing techniques promises further improvements in performance, cost-effectiveness, and sustainability. The potential applications extend beyond traditional airliners, including the development of more efficient and cost-effective smaller aircraft, drones, and even spacecraft.

The integration of advanced composites into the aerospace industry is not only about improving existing technologies but also about opening doors to entirely new possibilities in the design and construction of aircraft.

Material Properties and Manufacturing Techniques

Material Properties of Advanced Composites

Advanced composites, crucial in aerospace applications, exhibit exceptional material properties, distinguishing them from traditional materials. These properties stem from the unique structure of the composite, combining a strong, lightweight reinforcing phase (like carbon fiber or aramid) embedded within a polymer matrix. This combination results in high strength-to-weight ratios, crucial for minimizing aircraft weight and maximizing payload capacity, while also offering excellent fatigue resistance, vital for the durability of aircraft components under repeated stress cycles.

The exceptional stiffness of advanced composites allows for the creation of components with precise dimensional stability even under extreme conditions. This translates to reduced structural deformation, ensuring accurate functionality of the aircraft over its lifespan. Furthermore, the specific properties of different composite materials can be tailored through careful selection of the reinforcing fiber and matrix, making them adaptable to a wide range of demanding aerospace applications.

Manufacturing Techniques for Composite Materials

Several manufacturing techniques are employed to fabricate advanced composite components, each with its own advantages and limitations. Techniques like filament winding and pultrusion are crucial for producing continuous fiber-reinforced composite structures. Filament winding, for instance, involves winding continuous fibers around a mandrel to create complex shapes, while pultrusion extrudes a composite material through a die to produce uniform profiles, such as beams or rods.

Other methods, including prepreg layup and resin transfer molding (RTM), are used to create complex composite parts. Prepreg layup involves stacking pre-impregnated fiber layers and curing them under pressure and heat, while RTM injects resin into a mold containing fiber reinforcements. The choice of manufacturing technique significantly impacts the final properties and cost of the composite component, influencing design decisions for aerospace applications.

Fiber Types and Their Properties

The choice of fiber significantly impacts the performance of a composite material. Carbon fiber, renowned for its high strength-to-weight ratio and stiffness, is widely used in aerospace applications. Aramid fibers, on the other hand, exhibit exceptional impact resistance and are often used in protective structures. Each fiber type possesses unique mechanical characteristics, influencing the overall performance of the composite material and its suitability for specific aerospace applications.

Glass fibers, while less expensive than carbon fibers, are still used in some applications due to their good balance of strength and cost-effectiveness. The selection of the appropriate fiber type depends on the specific requirements of the aerospace component, considering factors like desired strength, stiffness, and cost-effectiveness. Different fiber types offer different advantages, and the optimal choice will depend on the specific application.

Matrix Materials and Their Impact

The matrix material, often a polymer resin, plays a crucial role in the overall performance of the composite material. Epoxy resins, known for their high strength, stiffness, and adhesion to fibers, are commonly used in aerospace composites. Other matrix materials, like polyester or phenolic resins, offer alternative properties and cost advantages, depending on the application.

Design Considerations for Composite Structures

Designing composite structures for aerospace applications necessitates careful consideration of various factors. Factors like fiber orientation, stacking sequences, and material properties are crucial for achieving the desired mechanical performance. Sophisticated analysis techniques, such as finite element analysis (FEA), are employed to model and simulate the behavior of composite structures under different loading conditions. Such analysis helps ensure structural integrity and performance, reducing the risk of failure under operational stresses.

Quality Control and Testing Procedures

Ensuring the quality and reliability of advanced composite components is paramount in aerospace applications. Rigorous quality control measures are implemented throughout the manufacturing process, from raw material inspection to final component testing. Testing procedures, including tensile testing, fatigue testing, and impact testing, are crucial for evaluating the performance characteristics of the composites and confirming their suitability for demanding aerospace environments. These tests help guarantee the safety and reliability of aircraft components made from advanced composites.

Environmental Impact and Sustainability

The environmental impact of composite materials and their manufacturing processes is an increasingly important consideration in aerospace design. Efforts are being made to develop more sustainable manufacturing processes and use recycled or bio-based materials in composite components. The recyclability and potential for reuse of composite materials are also factors in reducing the environmental footprint of aerospace applications. Addressing these concerns is crucial for maintaining the viability of advanced composites in the future of aerospace.

Applications Across the Aerospace Spectrum

Aircraft Design and Engineering

Aircraft design and engineering heavily rely on simulations to optimize performance, reduce weight, and enhance safety. Computational fluid dynamics (CFD) plays a crucial role in analyzing airflow patterns around aircraft, predicting lift and drag, and identifying areas for aerodynamic improvements. These simulations are used to model various flight conditions, enabling engineers to evaluate the aircraft's response and identify potential issues before physical prototypes are built.

Advanced design tools allow engineers to explore a vast design space, testing different configurations and materials. This iterative process significantly reduces the time and cost associated with traditional design methods. The ability to virtually test designs allows for a more thorough and efficient development process, leading to more optimized and safer aircraft.

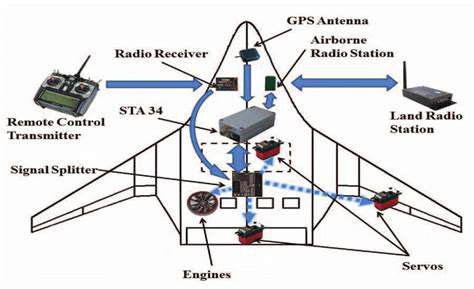

Flight Control Systems

Sophisticated flight control systems, crucial for safe and reliable operation, are also heavily influenced by simulation. Flight simulators allow pilots to practice various maneuvers and emergency procedures in a safe and controlled environment, enhancing their skills and preparedness. These simulations can also be used to train maintenance personnel on troubleshooting and repair procedures.

Simulations are vital for testing and validating the performance of complex flight control algorithms. This helps ensure that the system responds accurately and predictably to various flight conditions, improving safety and handling characteristics.

Propulsion Systems

The design and optimization of aircraft propulsion systems, such as jet engines and turboprops, heavily benefit from simulations. These simulations allow engineers to analyze the performance of different engine configurations under various operating conditions, enabling them to achieve maximum efficiency and reduce emissions.

Simulations can predict engine performance in different flight regimes, from takeoff and landing to cruise flight. This allows for the identification of potential issues and the implementation of corrective measures before they become problems in the real world.

Materials Science and Engineering

The aerospace industry demands high-performance materials with specific properties, such as strength, lightness, and resistance to extreme temperatures. Simulations allow engineers to explore the behavior of different materials under various loads and environmental conditions, predicting their performance and durability.

Material selection and design are significantly impacted by the use of simulations. This process allows for the optimization of material properties and the identification of potential failure points, leading to stronger and more reliable components.

Aerospace Manufacturing

Simulation techniques are increasingly used in the manufacturing processes of aerospace components. Optimizing manufacturing processes through simulation helps reduce production time, minimize waste, and improve quality control. Simulations can model the entire manufacturing process, from material cutting and shaping to assembly and inspection.

Predictive maintenance can also be implemented using simulations, allowing for the early identification of potential equipment failures and reducing downtime. This ultimately leads to significant cost savings and improved efficiency in the manufacturing process.

Space Exploration Applications

Simulation plays a critical role in space exploration, enabling engineers to design spacecraft, simulate trajectories, and analyze mission scenarios in a virtual environment. This is crucial for testing the spacecraft's performance and reliability in the harsh conditions of space.

These simulations are essential for ensuring the success of complex space missions by identifying potential risks and developing contingency plans. The ability to virtually test and refine designs significantly reduces the risk and cost associated with space missions.

Safety and Reliability Analysis

Safety and reliability analysis in aerospace applications are critical to ensure the safety of the aircraft, its occupants, and the surrounding environment. Simulations are used to assess the structural integrity of aircraft components under various stress conditions and to identify potential failure points. This allows engineers to design stronger, safer components.

Through simulations, potential hazards and risks can be identified and mitigated. This process significantly reduces the risk of catastrophic failures and ensures a higher level of safety and reliability for all aerospace applications.

Challenges and Future Directions

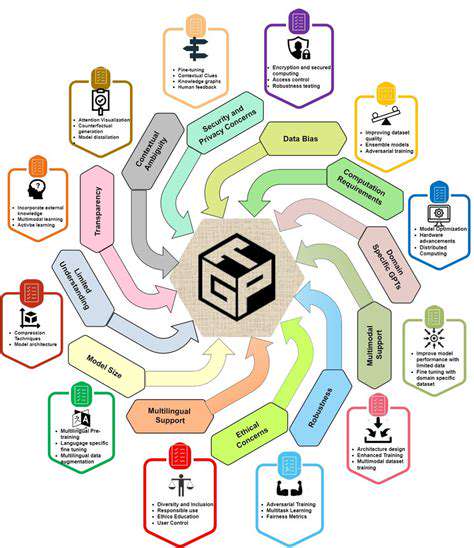

Addressing the Ethical Implications

The rapid advancement of artificial intelligence (AI) presents a complex array of ethical dilemmas that demand careful consideration. These issues extend beyond simple concerns of bias and fairness; they delve into the fundamental question of AI's role in society and its potential impact on human values. We must proactively address the potential for misuse, ensuring that AI systems are developed and deployed responsibly, aligning with human needs and ethical principles. This includes establishing robust oversight mechanisms and fostering open dialogue amongst stakeholders.

Optimizing for Scalability and Efficiency

As AI systems become more intricate and powerful, the need for scalable and efficient architectures becomes paramount. This necessitates innovative approaches to data management, processing, and model deployment. Efficient algorithms and optimized hardware are critical for AI systems to handle large datasets and complex tasks at a speed and scale that meet the demands of real-world applications. Significant investment in research and development is required to address these challenges.

Ensuring Robustness and Reliability

The reliability of AI systems is critical in various applications, from autonomous vehicles to medical diagnostics. Robustness is essential to ensure that AI systems function correctly in diverse and unpredictable environments, minimizing the risk of errors and failures. Ongoing research and rigorous testing are needed to identify and mitigate potential vulnerabilities, guaranteeing the safety and accuracy of AI-powered solutions. This requires a multifaceted approach involving rigorous validation and continuous monitoring.

Overcoming Data Limitations and Bias

The quality and quantity of data available significantly impact the performance and reliability of AI models. Significant challenges exist in acquiring, processing, and managing large, diverse datasets that accurately reflect the real world. Addressing inherent biases in datasets is crucial to prevent AI systems from perpetuating or amplifying existing societal inequalities. Developing effective methods for data augmentation and bias mitigation is vital for building fair and unbiased AI systems.

Fostering Collaboration and Knowledge Sharing

The advancement of AI is a collaborative effort requiring extensive knowledge sharing and cross-disciplinary collaboration. Fostering open communication and cooperation between researchers, developers, policymakers, and the public is essential for navigating the complex challenges ahead. This includes facilitating the exchange of best practices, research findings, and ethical guidelines to ensure that AI development aligns with societal values and goals. Creating accessible platforms for knowledge sharing is imperative.

Exploring Novel Applications and Use Cases

The potential applications of AI are vast and continuously expanding. Exploring new use cases across diverse sectors, such as healthcare, finance, and education, is crucial to unlock the transformative power of AI. This includes understanding how AI can improve existing processes, automate tasks, and create entirely new possibilities. Encouraging innovation and entrepreneurship in the AI space is key to unlocking these possibilities.

Maintaining Public Trust and Transparency

Building public trust in AI is paramount for widespread adoption and responsible deployment. Maintaining transparency and explainability in AI systems is essential to foster understanding and confidence in these technologies. Clearly communicating how AI systems work, their limitations, and their potential impact on society is crucial. This includes establishing clear ethical guidelines and regulatory frameworks to ensure that AI development and deployment are aligned with public interest.

The Economic and Environmental Impact

Economic Impacts of the Crisis

The recent economic downturn has had a profound impact on various sectors, significantly affecting employment and consumer spending. Businesses have faced unprecedented challenges in maintaining profitability and adapting to the evolving market conditions. Reduced consumer confidence and decreased investment have led to a notable contraction in economic activity across the board. This has triggered a ripple effect, impacting supply chains, disrupting production processes, and ultimately leading to job losses in numerous industries. Many small businesses, particularly those reliant on tourism or hospitality, have struggled to survive the crisis, highlighting the vulnerability of the economy to external shocks.

The crisis has also exposed the fragility of certain economic structures. The reliance on global supply chains has proven to be a double-edged sword, as disruptions in one region can quickly cascade through the entire system, impacting businesses and consumers globally. This underscores the need for greater resilience and diversification in economic strategies, particularly in sectors heavily reliant on international trade. Furthermore, the crisis has highlighted the importance of government intervention in supporting businesses and individuals during times of economic hardship. Policies aimed at stimulating economic growth and providing financial relief have become crucial in mitigating the negative consequences of the crisis.

Environmental Considerations

The economic downturn, while presenting significant challenges, has also presented an unexpected opportunity to address pressing environmental concerns. Reduced industrial activity and decreased transportation have led to a noticeable improvement in air and water quality in some regions, demonstrating a clear link between economic activity and environmental health. This presents a compelling argument for sustainable practices and the long-term benefits of prioritizing environmental protection.

However, the crisis also presents complex challenges for environmental protection efforts. Reduced funding for environmental initiatives and decreased public awareness could potentially hinder ongoing conservation efforts and lead to a decline in environmental regulations. The economic pressures may incentivize short-term solutions that come at the expense of long-term environmental sustainability. It is imperative that governments and businesses prioritize environmental considerations alongside economic recovery efforts to ensure a sustainable and resilient future. A focus on green technologies and sustainable practices can help create new jobs and stimulate economic growth while safeguarding the environment.

Furthermore, the crisis has highlighted the interconnectedness of economic and environmental systems. The impact of environmental degradation, such as deforestation and climate change, can have severe economic consequences, including decreased agricultural yields, increased natural disasters, and the displacement of populations. Therefore, a holistic approach to economic recovery must incorporate environmental considerations to ensure long-term sustainability and resilience.