Beyond Traditional Methods: Exploring Innovative Approaches

Traditional methods, while often reliable, can sometimes fall short in addressing the complexities of modern challenges. Innovative approaches, grounded in creativity and a willingness to explore uncharted territory, offer a compelling alternative. This shift towards novel solutions necessitates a departure from the familiar and a proactive embrace of experimentation and adaptability. It often requires a significant investment in research and development, but the potential rewards can be substantial.

These innovative methods often involve a multifaceted approach, drawing on insights from diverse fields and perspectives. This interdisciplinary collaboration fosters a richer understanding of the problem and unlocks a wider range of potential solutions. By challenging established norms and embracing new possibilities, we can unlock solutions that were previously unimaginable.

The Role of Technology in Shaping New Approaches

Technological advancements have become indispensable tools in forging new pathways. Sophisticated algorithms, powerful computing capabilities, and advanced data analysis techniques are transforming industries and reshaping how we approach problem-solving. This technological revolution is enabling us to process vast amounts of information, identify intricate patterns, and ultimately, predict future trends more accurately.

Automation and machine learning are playing a crucial role in streamlining processes and enhancing efficiency. These technologies not only increase productivity but also free up human resources to focus on more strategic and creative tasks. This shift in focus is essential for fostering innovation and adaptability in the face of rapidly evolving circumstances.

Embracing Collaboration and Knowledge Sharing

Collaboration is paramount to successful innovation. By bringing together diverse perspectives and expertise, we can overcome limitations and achieve breakthroughs that would be impossible to achieve in isolation. This collaborative spirit transcends geographical boundaries and fosters a sense of shared responsibility in addressing global challenges.

Knowledge sharing is essential for the dissemination of new ideas and the acceleration of progress. Open access to information, coupled with platforms for knowledge exchange, empowers individuals and organizations to contribute to the collective pool of understanding. This collaborative environment allows for the rapid dissemination of new insights and the fostering of innovation within communities.

Adapting to Change and Embracing Flexibility

The ability to adapt to change is critical in today's dynamic environment. Flexible approaches, characterized by a willingness to adjust strategies in response to evolving circumstances, are crucial for navigating uncertainty and achieving desired outcomes. This adaptability allows us to respond effectively to unforeseen challenges and capitalize on emerging opportunities.

Embracing a mindset of continuous learning and improvement is essential. A commitment to staying informed about new developments and trends allows us to anticipate future needs and adapt our strategies accordingly. This proactive approach to change fosters resilience and ensures that we remain relevant and effective in a rapidly changing world.

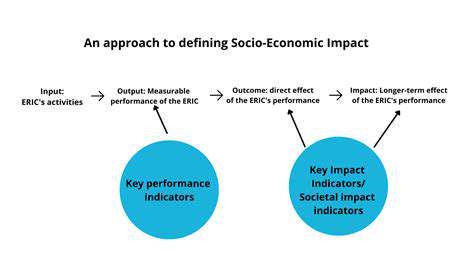

The Importance of Measuring Success Beyond Traditional Metrics

Traditional metrics often fail to capture the full scope of success in innovative endeavors. Evaluating outcomes based solely on quantifiable data can lead to a narrow perspective that overlooks the broader impact and long-term benefits. Developing new evaluation frameworks is crucial for recognizing the multifaceted nature of success in the context of innovation.

These frameworks should consider qualitative factors, including social impact, environmental sustainability, and the overall improvement of quality of life. By encompassing these considerations, we can foster a more comprehensive understanding of the true value of innovative solutions. This holistic approach to measurement ensures that we are evaluating not only the effectiveness but also the ethical implications and societal impact of our innovations.

Tailored Design for Enhanced Performance

Tailored Design Flexibility

Additive manufacturing (AM), also known as 3D printing, offers unparalleled design flexibility in rocketry. Traditionally, rocket components are constrained by the limitations of subtractive manufacturing processes. This leads to designs that often sacrifice performance for ease of fabrication. AM allows engineers to create intricate, lightweight structures that optimize the distribution of materials for maximum strength and minimal weight, dramatically enhancing the performance characteristics of the rocket.

This design freedom extends to the creation of complex internal cavities and cooling channels within rocket components. These tailored features can significantly improve heat dissipation and reduce thermal stress, leading to increased reliability and operational lifespan. This ability to tailor the design for specific performance needs is a major advantage of AM in the rocketry industry.

Improved Material Utilization

AM allows for the precise placement of materials, minimizing wasted material and maximizing the utilization of available resources. This is crucial in rocketry, where lightweight materials are essential for maximizing payload capacity and range. The ability to strategically place reinforcement structures and optimize material distribution directly translates to improved performance metrics.

Furthermore, using AM, engineers can incorporate multiple materials into a single component. This enables the design of composite structures that leverage the strengths of different materials to create a stronger, lighter, and more resilient rocket part. This multi-material capability is virtually impossible with traditional manufacturing techniques.

Enhanced Structural Integrity

The intricate geometries achievable with AM can result in enhanced structural integrity within rocket components. Complex internal support structures, optimized for stress distribution, can significantly increase the load-bearing capacity of the parts. This translates to a more robust and resilient rocket capable of withstanding the extreme forces encountered during launch and flight. Traditional manufacturing often employs a more simplistic approach to structural design, which can lead to performance limitations.

Reduced Manufacturing Time and Costs

AM significantly reduces the time required for prototyping and manufacturing. The ability to rapidly produce and test different design iterations accelerates the design cycle, enabling engineers to quickly identify and refine optimal designs. This rapid prototyping capability translates into faster development cycles, helping rocket manufacturers stay competitive in the market. This, in turn, can lead to a reduction in overall development costs.

Advanced Cooling and Thermal Management

Additive manufacturing enables the creation of complex cooling channels and heat sinks within rocket components. These channels can be precisely designed to dissipate heat generated during operation, preventing overheating and component failure. The ability to tailor cooling strategies directly enhances the reliability and longevity of rocket engines and other critical components. This sophisticated approach to thermal management is a key factor in achieving longer operational lifespans and higher performance.

Material Exploration and Innovation

Material Exploration for Enhanced Performance

Additive manufacturing (AM) is revolutionizing the way we approach material exploration in rocketry. By enabling the creation of complex geometries and intricate structures previously impossible to produce using traditional methods, AM opens doors to exploring novel materials and combinations for improved performance characteristics. This exploration allows engineers to optimize material properties like strength, stiffness, and thermal resistance for specific components within the rocket, leading to more efficient and reliable designs.

Researchers are actively investigating the use of advanced composites, reinforced polymers, and metal alloys tailored for high-temperature environments. The ability to create intricate internal cooling channels and supporting structures within rocket components allows for enhanced heat management, minimizing thermal stress and maximizing component lifespan.

Innovation in Component Design and Function

The inherent flexibility of AM facilitates the development of highly innovative component designs that traditional manufacturing methods struggle to replicate. These designs often result in lighter, stronger, and more efficient components. This is particularly crucial in rocketry, where weight reduction is paramount for maximizing payload capacity and improving overall performance.

AM enables the creation of complex internal structures within rocket components, such as fuel tanks, combustion chambers, and nozzles. These intricate structures can be optimized for specific performance requirements, potentially leading to significant improvements in thrust, efficiency, and overall rocket performance. The ability to integrate complex cooling channels directly into the component design is another significant benefit.

Advanced Manufacturing Processes for Complex Structures

Additive manufacturing processes themselves are constantly evolving, leading to advancements in material deposition, layer-by-layer control, and post-processing techniques. These advancements are crucial for ensuring the structural integrity, dimensional accuracy, and performance characteristics of the AM-produced components. The development of specialized AM processes tailored for specific materials and applications further enhances the potential for innovation in rocketry.

New AM processes are being developed to handle a wider range of materials, including advanced metal alloys and composites. This allows for greater design freedom and the potential to create components with unique functionalities. The ability to produce intricate lattice structures and other optimized geometries through AM contributes to the overall efficiency and performance of rocket components. This further pushes the boundaries of what is possible in the field of rocket propulsion.

Sustainability and Cost-Effectiveness in Material Selection

Material exploration through AM also considers sustainability. The ability to use recycled materials or alternative materials with a smaller environmental footprint is a critical aspect of future rocket design. AM allows for the exploration of such materials in a more efficient and cost-effective manner than traditional methods. The potential for reduced material waste and optimized component design is a significant contribution to the sustainability of rocket development.

Exploring cost-effective materials and processes is crucial for making AM applications viable in rocketry. The potential for reduced material usage, optimized designs, and the use of recycled materials can lead to a significant reduction in the overall cost of rocket components. This, in turn, could facilitate broader adoption of AM in the aerospace industry and make rocket technology more accessible.

The Future of AM in Space Exploration

Advancements in Propulsion Systems

The future of space exploration hinges significantly on advancements in propulsion systems. Current methods, while functional, often suffer from limitations in terms of speed and efficiency. Developing innovative propulsion technologies, such as advanced ion drives, plasma thrusters, and potentially even nuclear fusion propulsion, is crucial for achieving faster transit times to distant destinations. These advancements will enable us to reach further into the solar system and beyond, opening up previously unimaginable possibilities for exploration and scientific discovery. This includes the potential for establishing permanent human settlements on other celestial bodies.

Exploring alternative propulsion methods that are not reliant on traditional chemical rockets is essential. These new technologies offer the potential for dramatically faster travel times, significantly reducing the time it takes to reach destinations like Mars or beyond. This is vital for missions requiring rapid responses to unforeseen events, and for long-duration missions where crew health and morale are critical factors. The exploration of space demands the development of propulsion systems that are not only powerful but also sustainable and safe for long-duration missions.

Beyond the technical challenges, the economic factors related to propulsion development must also be considered. The costs associated with research and development, testing, and manufacturing of new propulsion systems are significant. However, the potential rewards in terms of scientific discovery, technological advancement, and the expansion of human knowledge far outweigh these costs. Investing in these advancements will undoubtedly lead to a paradigm shift in our ability to explore the cosmos.

Expanding the Scope of Spacecraft Design

As we look towards the future of space exploration, the design of spacecraft themselves needs a significant overhaul. Current spacecraft are often limited in terms of their size, payload capacity, and adaptability. The evolution of space exploration demands spacecraft capable of accommodating larger crews, more complex experiments, and adapting to unforeseen circumstances. This includes developing innovative designs that are more resilient to the harsh environments of space, and which prioritize the safety and well-being of the crew.

Crucially, future spacecraft must be designed with a focus on sustainability and reusability. Reducing the environmental footprint of space travel is paramount. Reusable spacecraft will greatly reduce the cost of future missions, allowing for more frequent and cost-effective expeditions. This will further enable the study of a wider range of celestial bodies and phenomena.

Moreover, future spacecraft should be designed with enhanced capabilities for autonomous operation. This will reduce the need for constant human intervention, enabling the spacecraft to adapt and respond more efficiently to the challenges of space exploration. Advanced robotic systems and AI will play a pivotal role in this evolution, allowing for more independent and prolonged missions.