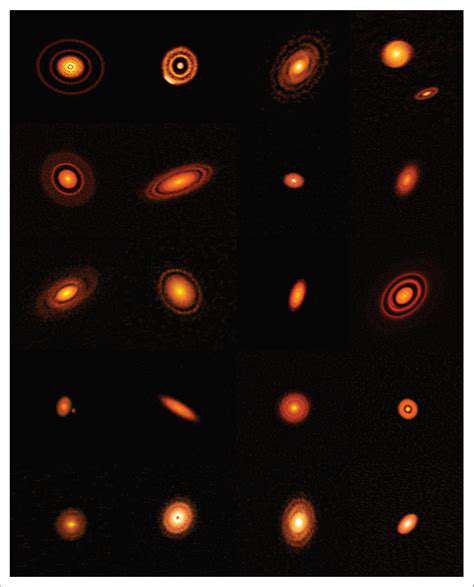

Space-based manufacturing represents a groundbreaking shift in material production, overcoming the constraints of terrestrial facilities. The microgravity environment enables the fabrication of materials with unparalleled properties and structures, unattainable under Earth's gravitational pull. This breakthrough paves the way for novel alloys, composites, and advanced materials boasting superior strength, durability, and functionality.

Consider the implications for lightweight yet robust spacecraft components or cutting-edge medical implants. The absence of atmospheric interference in space allows for meticulous control and refinement of manufacturing techniques, yielding products of exceptional quality.

Resource Acquisition in Space

Space harbors abundant resources, such as asteroids and lunar regolith. Harvesting and processing these materials in situ eliminates the energy-heavy transportation of Earth-sourced raw materials, slashing costs and environmental harm. This resource abundance fosters the establishment of sustainable industrial operations beyond our planet.

Reduced Environmental Impact

Terrestrial manufacturing processes frequently contribute to pollution and resource exhaustion. Space-based production, by minimizing the need for material transport and Earth-bound resource extraction, can substantially alleviate these adverse effects. This transformative approach could redefine our planetary stewardship and promote sustainability.

Reduced Manufacturing Costs

Although initial space infrastructure investments appear daunting, the long-term economic benefits are compelling. Space-based manufacturing can dramatically lower material and product expenses by bypassing costly transportation and diminishing Earth's manufacturing footprint. This efficiency could translate to reduced consumer prices and broader market accessibility.

Enhanced Security and Strategic Advantages

Establishing manufacturing capabilities in space provides nations with critical security and strategic benefits. These facilities can produce essential materials and components for defense and technological progress, reducing reliance on terrestrial supply chains and bolstering national autonomy.

Access to Unique Manufacturing Capabilities

The low-gravity environment facilitates entirely novel manufacturing methodologies. These innovative techniques could yield high-value materials with unprecedented characteristics. This exclusive access to space-based production is pivotal for driving technological breakthroughs and expanding material science frontiers.

Overcoming Challenges in Space-Based Material Testing

Challenges in Simulating Zero-Gravity Environments

Replicating space's microgravity remains a formidable obstacle in material testing. Earth-based simulations, though informative, often fail to fully emulate weightlessness, potentially skewing predictions of material behavior in space. Researchers continuously refine techniques, employing advanced vibration isolation and centrifuges to better approximate zero-gravity conditions.

The lack of atmospheric drag and other terrestrial forces further complicates accurate space environment simulation, necessitating ongoing research to capture these critical factors.

Radiation Exposure and its Effects on Materials

Space materials face constant bombardment by cosmic radiation and solar particles, which can disrupt atomic structures and degrade mechanical properties. Developing radiation-resistant materials and precise simulation methods is crucial for ensuring long-term material performance in space.

Prolonged radiation exposure may weaken structural integrity, underscoring the need for comprehensive understanding of cumulative radiation effects.

Maintaining Material Integrity Under Extreme Temperatures

Space's drastic temperature swings – from intense heat to extreme cold – challenge material stability. Engineers must develop thermally resilient materials and implement effective thermal management systems to protect space assets throughout missions.

Vacuum Conditions and Their Impact on Material Properties

Space's near-vacuum environment alters material behavior in ways difficult to replicate on Earth, requiring innovative testing approaches to account for these unique conditions.

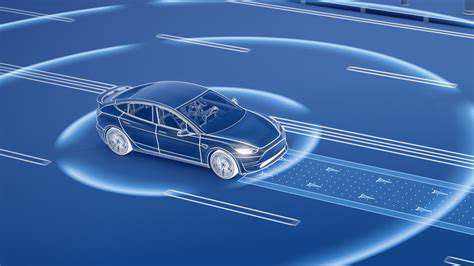

Testing the Durability of Materials in Micrometeoroid Environments

Micrometeoroids and space debris pose constant threats to spacecraft. Developing impact-resistant materials and accurate impact simulation techniques is essential for protecting space infrastructure.

The Cost and Complexity of Space-Based Testing

Space testing presents significant financial and logistical challenges, driving research into more cost-effective Earth-based simulation methods that maintain accuracy in material characterization.

Future Directions and Implications

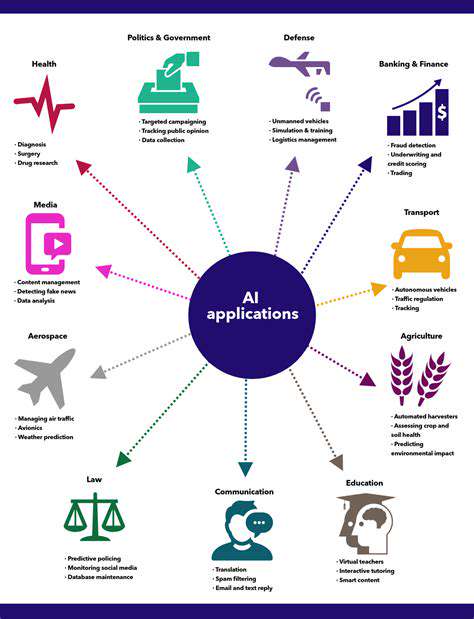

Potential Applications in Diverse Fields

This technology promises transformative impacts across medicine, agriculture, environmental monitoring, and materials science. Potential breakthroughs include early disease detection, precision agriculture, novel construction materials, and enhanced ecosystem monitoring systems.

The applications extend beyond current imagination, poised to revolutionize numerous aspects of human life and industry.

Ethical Considerations and Societal Impact

As this technology advances, addressing ethical concerns and ensuring equitable access must remain priorities. Key discussions should focus on data privacy, algorithmic bias, and workforce transitions.

Proactive workforce development strategies will be crucial to mitigate job displacement effects. Collaborative efforts among governments, industries, and educational institutions can facilitate smooth societal adaptation.