Introduction to Aerospace Robotics for Assembly

Defining Aerospace Robotics

Aerospace robotics encompasses a broad field encompassing the design, development, and application of robots operating within the aerospace environment. This includes, but isn't limited to, robots used in spacecraft assembly, maintenance, and exploration. The unique challenges of the space environment, such as extreme temperatures and the lack of a breathable atmosphere, significantly influence the design and operational parameters of these robots. These robots must be incredibly robust and reliable to function effectively in such demanding conditions.

Understanding the fundamental principles of robotics, coupled with an in-depth knowledge of aerospace engineering, is crucial for success in this interdisciplinary field. This necessitates a strong foundation in mechanics, control systems, and materials science, alongside a comprehensive understanding of the specific requirements of the aerospace domain.

Applications in Space Exploration

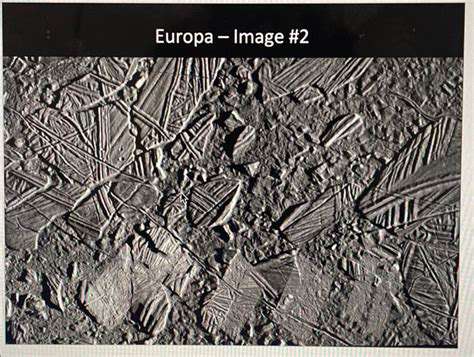

One key application of aerospace robotics is in space exploration. Robots can perform tasks that are too hazardous or time-consuming for human astronauts, such as exploring distant planets, collecting samples, and conducting scientific experiments in harsh environments. These robotic missions can significantly broaden our understanding of the universe and contribute to scientific discoveries.

For instance, rovers on Mars, like Curiosity and Perseverance, are prime examples of aerospace robots performing complex tasks remotely. Their ability to navigate challenging terrains and conduct sophisticated analyses of Martian soil and rocks is vital for our planetary science endeavors.

Challenges in Aerospace Robotics

Developing and deploying aerospace robots presents numerous significant challenges. One major hurdle is the stringent requirements imposed by the space environment, including the need for extreme reliability and redundancy to ensure mission success. The lack of direct human intervention necessitates sophisticated autonomous systems capable of handling unexpected situations and adapting to changing conditions.

Furthermore, the high cost of space missions and the need for precise control and navigation pose considerable engineering hurdles. These factors necessitate the use of advanced technologies and innovative solutions.

Design Considerations for Spacecraft Maintenance

The maintenance of spacecraft in orbit is another crucial application of aerospace robotics. Robots can perform critical tasks like repairing damaged components, replacing worn-out parts, and conducting inspections without the risks associated with human spacewalks. This approach can significantly reduce mission costs and improve the longevity of spacecraft.

Designing robots for spacecraft maintenance requires a careful consideration of the specific constraints of the space environment. Factors such as limited space, extreme temperatures, and the absence of gravity must be meticulously accounted for in the design process.

Autonomous Navigation Systems

Autonomous navigation systems are critical for the success of aerospace robots. These systems must be highly reliable and capable of adapting to unforeseen circumstances encountered during space missions. Sophisticated algorithms and sensor technologies are essential for navigating complex terrains and performing precise maneuvers. Ensuring accurate and consistent data processing within the constraints of space is paramount.

The complexity of these systems often necessitates the integration of multiple sensors, such as cameras, lidar, and radar, to build a comprehensive understanding of the environment. Developing robust algorithms for decision-making and control is also a key aspect of designing effective autonomous navigation systems.

Future Trends and Advancements

The field of aerospace robotics is constantly evolving, with new technologies and advancements emerging regularly. Future developments are likely to focus on more sophisticated robotic systems capable of performing increasingly complex tasks in space. Advancements in artificial intelligence and machine learning will play a crucial role in enabling greater autonomy and adaptability in these robots.

The potential for collaborative robots, where human operators and robotic systems work together, is also a promising area of research. This approach could enhance mission efficiency and safety, paving the way for more ambitious space exploration endeavors.

Advantages of Aerospace Robotics in Assembly

Enhanced Precision and Repeatability

Aerospace robotics, with their advanced control systems and intricate sensors, offer unparalleled precision in assembly tasks. This precision translates directly into higher quality components and assemblies, crucial for the safety and reliability of aerospace vehicles. The ability to consistently repeat complex movements with micron-level accuracy minimizes errors inherent in human assembly, leading to significant improvements in the overall quality and consistency of the final product. Furthermore, this precision allows for the assembly of intricate components that would be challenging, if not impossible, for human operators to achieve.

The repeatability aspect of aerospace robotics is vital for ensuring consistent tolerances in critical areas of the assembled product. This consistency contributes to the overall reliability and performance of the aerospace vehicle, a critical factor in safety-critical applications.

Improved Efficiency and Productivity

Automation, a core principle of aerospace robotics, dramatically boosts productivity by performing tasks 24/7 without fatigue or breaks. This continuous operation significantly reduces assembly time compared to manual processes, leading to faster turnaround times and increased production capacity. The reduced cycle time translates into significant cost savings and increased overall efficiency in the manufacturing process.

Furthermore, robotic systems can handle multiple assembly tasks simultaneously, further enhancing production efficiency. This multi-tasking capability allows for the optimization of the assembly line and the efficient allocation of resources, ultimately leading to a more streamlined and productive manufacturing environment.

Reduced Labor Costs and Improved Safety

Aerospace assembly often involves hazardous materials and processes. Deploying robots in these environments minimizes human exposure to these risks, contributing significantly to worker safety. This reduction in workplace hazards leads to a safer working environment and a reduction in the potential for costly accidents and injuries.

Beyond safety, robotics also significantly reduce labor costs. While initial investment in robotic systems can be substantial, the long-term cost savings from increased productivity, reduced labor, and minimized downtime often outweigh initial investment. This economic benefit is particularly significant in high-volume aerospace production.

Increased Flexibility and Adaptability

Aerospace robots can be reprogrammed and reconfigured relatively easily to accommodate different assembly tasks and product variations. This adaptability is crucial in the aerospace industry, where product designs and specifications frequently evolve. The ability to quickly retool robots for new models or modifications minimizes downtime and maximizes the return on investment in the robotic system. This flexibility also allows for the rapid response to changes in production demands and evolving design requirements.

Enhanced Quality Control and Inspection Capabilities

Integrating robots with advanced sensors and vision systems allows for real-time quality control during the assembly process. This integration allows for the detection of defects or deviations from specifications, enabling immediate corrective action and preventing the assembly of faulty components. The incorporation of these inspection capabilities leads to a higher quality final product with fewer defects that might have been missed in a purely human-operated assembly process.

Automated inspection processes can also detect subtle variations or defects that might be difficult or time-consuming for human inspectors to identify. This leads to a higher level of accuracy and reliability in the overall quality control process.

Types of Aerospace Robots and Their Applications

Types of Aerospace Robots

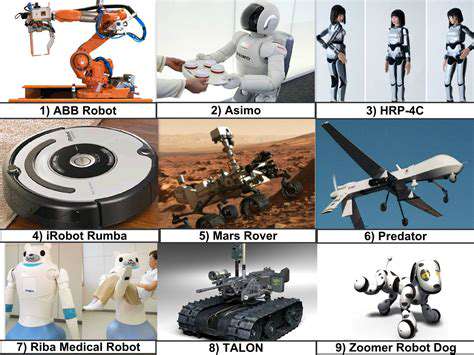

Aerospace robots encompass a wide range of automated systems designed for tasks in the aerospace industry, from manufacturing and maintenance to space exploration. These robots are crucial for increasing efficiency, safety, and precision in various aerospace applications. They often operate in harsh environments and demanding conditions, requiring robust design and sophisticated control systems.

Different types of aerospace robots are tailored to specific tasks and environments. Understanding these variations is crucial for selecting the appropriate robot for a given application. This understanding enables optimal performance and resource allocation within the aerospace sector.

Manufacturing Robots

Manufacturing robots play a vital role in the aerospace industry, automating tasks like welding, painting, and assembly. These robots are highly precise and capable of performing complex operations with remarkable consistency, leading to improved product quality and reduced manufacturing time. They can handle delicate components and ensure precise placement in demanding aerospace manufacturing processes.

These robots often incorporate advanced sensors and vision systems, enabling them to adapt to variations in parts and ensure high-quality assembly. This enhances the production process and reduces errors inherent in manual processes.

Maintenance Robots

Maintenance robots are specifically designed for inspecting, repairing, and maintaining aircraft and spacecraft. Their ability to operate in confined spaces and hazardous environments makes them invaluable for tasks that are dangerous or difficult for human personnel. These robots can perform intricate inspections of hard-to-reach areas, significantly improving safety and efficiency in maintenance tasks.

They are equipped with specialized tools and sensors, allowing them to perform a wide array of maintenance tasks, from detecting corrosion to replacing components. This capability translates into significant cost savings and reduced downtime in the aerospace sector.

Inspection Robots

Inspection robots are crucial for verifying the quality and integrity of aerospace components. They are equipped with advanced sensors and imaging technologies to identify flaws, defects, and anomalies in structures and materials. This ensures the safety and reliability of aircraft and spacecraft. Robots can perform these inspections with incredible accuracy, far exceeding the capabilities of human inspectors.

These robots can be programmed to inspect intricate components, making them ideal for detecting hidden defects and ensuring the safety and reliability of aerospace products. Their non-invasive nature allows for thorough inspection without damaging the components under scrutiny.

Space Exploration Robots

Robots play an integral part in space exploration, carrying out tasks that are too hazardous or time-consuming for astronauts. These robots perform tasks like sample collection, surface analysis, and navigation in extraterrestrial environments. Their ability to endure the extreme conditions of space makes them invaluable for exploring and understanding our solar system.

These advanced robots often incorporate sophisticated navigation systems, allowing them to autonomously explore and map vast areas in space. This autonomous operation reduces the workload on human crews and opens up new possibilities for scientific discovery and technological advancement. They can handle the extreme temperatures and vacuum conditions of space.

Assembly Robots

Aerospace assembly robots are used in the complex process of building aircraft and spacecraft. They are responsible for assembling intricate parts and ensuring precise alignment and connections. These robots work alongside human engineers, creating a more efficient and less error-prone assembly process. Their precision and speed increase the rate of production.

Their ability to perform repetitive tasks with high accuracy reduces the risk of human error and increases the consistency of the assembly process. This is especially important in the aerospace industry, where even minor mistakes can have significant consequences.

Collaborative Robots (Cobots)

Collaborative robots, or cobots, are increasingly used in aerospace to enhance human-robot interaction. They are designed to work alongside human engineers and technicians, performing tasks that are both repetitive and require precise movements. This collaboration allows for increased efficiency and safety in the workplace. These robots are designed for interaction and safety with human workers.

Cobots are often equipped with advanced sensors and safety features, ensuring a safe working environment for both humans and robots. Their flexibility and adaptability make them an ideal solution for a wide range of aerospace tasks, allowing for a seamless transition in the workflow.