The Role of Nanotechnology in Aerospace Materials

Enhanced Strength and Durability

Nanotechnology offers a revolutionary approach to enhancing the strength and durability of aerospace materials, leading to lighter, more resilient components. By manipulating materials at the atomic and molecular level, engineers can create structures with exceptional mechanical properties. This translates into aircraft capable of withstanding greater stresses and operating under more demanding conditions, ultimately improving performance and safety. Aerospace applications benefit significantly from the increased resistance to fatigue and fracture that nanomaterials provide.

The incorporation of nanomaterials, such as carbon nanotubes and graphene, into composite materials can dramatically improve their tensile strength and impact resistance. This allows for the development of advanced aircraft structures with reduced weight, which in turn leads to enhanced fuel efficiency and reduced operating costs.

Improved Thermal Management

Nanotechnology plays a crucial role in improving the thermal management of aerospace components, especially in high-performance aircraft and spacecraft. Nanomaterials, possessing unique thermal conductivity properties, can be integrated into materials to enhance heat dissipation and reduce thermal stresses within critical components like engines and wings.

By strategically distributing nanomaterials within the matrix of existing materials, engineers can create structures that effectively manage heat, leading to reduced temperature fluctuations and improved component lifespan. This is particularly important in situations where extreme temperatures are encountered, such as during re-entry or hypersonic flight.

Lightweight Material Design

A key advantage of nanotechnology in aerospace materials is its ability to create remarkably lightweight yet robust materials. The atomic-level manipulation allows for the development of materials with superior strength-to-weight ratios compared to traditional materials. This is vital in aerospace applications, as reduced weight translates directly to improved fuel efficiency, payload capacity, and overall performance.

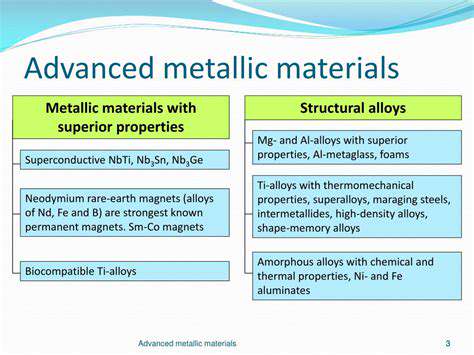

Nanomaterials like aluminum oxide nanoparticles can be incorporated into alloys to create lighter, yet stronger components. This weight reduction directly impacts the design and performance of aircraft, spacecraft, and missiles, leading to more efficient and effective systems.

Enhanced Corrosion Resistance

Aerospace components are frequently exposed to harsh environments, leading to corrosion and degradation. Nanotechnology offers promising solutions for enhancing the corrosion resistance of materials, extending their lifespan and ensuring reliable performance in demanding conditions.

Nanomaterials, such as titanium dioxide nanoparticles, can be used to create protective coatings that hinder the corrosive effects of moisture, oxygen, and other elements. These coatings effectively shield the underlying materials from degradation, ensuring extended operational lifespans and reduced maintenance requirements. This crucial aspect contributes significantly to the long-term reliability of aerospace systems.

Advanced Coatings and Surface Treatments

Nanotechnology enables the creation of advanced coatings and surface treatments that enhance the performance of aerospace materials in various ways. These coatings can improve the resistance to wear, abrasion, and erosion, resulting in extended component lifespans and reduced maintenance needs.

The precise control over nanostructures allows for the development of highly specialized coatings tailored to specific environmental conditions. For instance, coatings can be designed to improve the aerodynamic properties of aircraft surfaces, reducing drag and enhancing fuel efficiency. These advancements are pivotal for achieving peak performance in modern aerospace systems.

Improved Optical Properties

Nanomaterials offer unique optical properties that can be leveraged in aerospace applications. For example, nanostructured materials can be used to create transparent and lightweight components, crucial in optical systems for spacecraft and aircraft.

These materials can also enhance the reflectivity or absorptivity of components, impacting systems such as solar panels and thermal management systems. The ability to precisely control light interaction at the nanoscale opens up possibilities for developing innovative optical components with improved performance, reduced size, and weight.

Sustainable Manufacturing Practices

The development of nanomaterials and the implementation of nanotechnology in aerospace materials can contribute to more sustainable manufacturing practices. Some nanomaterials can be produced using less energy and fewer resources compared to traditional methods, reducing the environmental impact of aerospace manufacturing.

Furthermore, the enhanced performance and durability of nanomaterial-enhanced components can lead to a reduced need for frequent replacements, further minimizing waste and promoting a more circular economy within the aerospace industry. This sustainable approach is vital for mitigating the environmental footprint of the aerospace sector.