What are Sustainable Aviation Fuels?

Understanding Sustainable Aviation Fuels (SAFs)

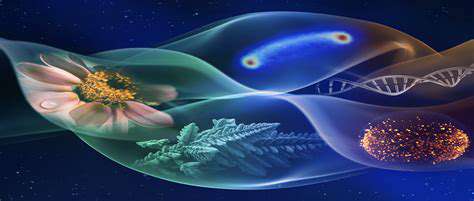

Unlike conventional jet fuels derived from fossil sources, Sustainable Aviation Fuels (SAFs) originate from renewable materials. These materials range from agricultural byproducts to recycled oils and algae biomass. What sets SAFs apart is their production process, which avoids competition with food supplies or critical land use. This positions them as a cornerstone for greener aviation.

Creating SAFs involves transforming these renewable inputs into fuels chemically identical to traditional jet fuel. This conversion demands specialized technology and rigorous environmental oversight across the entire supply chain.

Diverse Varieties of Sustainable Aviation Fuels

The SAF landscape features multiple fuel types, each with distinct production methods. Bio-based SAFs from crops or organic waste represent one major category. Another significant type is HEFA fuel, produced from vegetable oils and animal fats, offering a practical fossil fuel substitute.

Innovative SAF variants from non-food biomass demonstrate the potential of various renewable resources. This diversity in feedstock options highlights the adaptability of sustainable fuel solutions.

Environmental Advantages of SAF Implementation

SAFs' primary ecological benefit is their dramatically lower carbon footprint compared to conventional fuels. By replacing fossil-based jet fuel, SAFs can substantially reduce aviation's greenhouse emissions, making air travel more environmentally responsible. This emission reduction significantly lessens aviation's overall environmental impact.

Economic Realities and Development Hurdles

Current SAF production costs exceed those of traditional jet fuel, presenting adoption challenges for airlines. However, ongoing technological progress promises to reduce these costs over time.

Government support through incentives and policy frameworks proves crucial for SAF advancement. Measures promoting SAF production and airline adoption can accelerate the aviation sector's sustainable transformation.

Production Methods and Technological Innovation

SAF manufacturing processes vary by feedstock type, ranging from biomass conversion to oil refinement. Breakthroughs in catalytic technology and processing efficiency are key to making SAF production more viable.

Environmental responsibility must guide the entire SAF lifecycle, from raw material sourcing to distribution. This includes optimizing land use and maximizing resource efficiency throughout the process.

Infrastructure Requirements for Widespread Use

SAF adoption faces significant infrastructure challenges, including the need for specialized storage and distribution systems. Compatibility with existing aircraft fueling systems also requires attention.

Developing dedicated SAF infrastructure is essential for establishing a functional supply chain. This includes adapting current systems and creating new facilities tailored to SAF characteristics.

The Evolving Role of SAFs in Aviation

The outlook for sustainable aviation fuels appears bright, with continuous innovation driving progress. As production becomes more economical and technology advances, SAFs will play an increasingly vital role in aviation decarbonization. Policy support and industry cooperation will remain critical to widespread adoption.

Transitioning to SAFs presents a major opportunity to reduce aviation's environmental footprint while stimulating economic growth and technological development in the sector.

The Role of Policy and Investment in SAF Adoption

Policy Frameworks Driving SAF Implementation

Government initiatives significantly influence SAF adoption rates. Tax incentives, production subsidies, and usage mandates help bridge the cost gap between SAF and conventional fuels. These measures create favorable conditions for private investment and innovation in sustainable fuels.

Carbon pricing systems that penalize fossil fuel use while rewarding sustainable alternatives provide clear economic signals. Government procurement policies requiring SAF use can generate substantial market demand and stimulate supply chain development.

Investment Approaches for Scaling SAF Production

Substantial private capital is essential for expanding SAF production capacity. Investors require clear profitability pathways and supportive regulatory environments when evaluating SAF opportunities. Early-stage funding from venture capital plays a crucial role in supporting innovative producers.

Research and development investment remains paramount for advancing SAF technology. Funding for production efficiency improvements and novel feedstock development will be critical for cost reduction and market competitiveness.

Building the Necessary Infrastructure Foundation

Specialized infrastructure development is fundamental for SAF integration. This includes constructing dedicated storage facilities and modifying existing systems for SAF compatibility. Reliable infrastructure forms the backbone for market growth and reduces adoption barriers.

Expanding the aviation fuel network to accommodate SAF requires significant investment in storage and handling systems. Research into specialized SAF handling technologies will enhance operational safety and efficiency.

Financial Mechanisms Encouraging Adoption

Various financial instruments can promote SAF use, including government subsidies and carbon offset programs. These mechanisms help level the economic playing field with conventional fuels. Market-based approaches like carbon trading create financial incentives for emission reduction through SAF adoption.

Blending mandates and other regulatory measures can stimulate SAF production while aligning market forces with environmental objectives. Such mechanisms encourage technological innovation throughout the SAF value chain.

Challenges and Opportunities for SAF Development

Managing Global Supply Chain Complexities

International supply networks present significant logistical challenges for SAF implementation. Disruptions from global events can ripple through entire production and distribution systems, necessitating robust risk management strategies.

Effective supply chain oversight requires comprehensive understanding of each operational stage, from raw material procurement to final delivery. Building strong supplier relationships and developing contingency plans are essential for stability.

Technology's Transformative Impact

Emerging technologies are revolutionizing SAF production and distribution. Automation and data analytics enable greater efficiency and cost reduction throughout the value chain. Companies leveraging these innovations gain significant competitive advantages.

Technology adoption brings challenges including substantial capital requirements and workforce adaptation needs. Organizations must carefully balance these factors when implementing new systems.

Sustainability as a Competitive Advantage

Growing consumer demand for environmentally responsible products makes sustainability a key differentiator. Companies prioritizing sustainable practices throughout their supply chains strengthen brand loyalty and market position.

Achieving true sustainability requires comprehensive approaches that extend beyond company operations to include all supply chain partners. This encompasses environmental protection and fair labor practices.

Responding to Evolving Market Demands

Shifting consumer preferences require agile response capabilities. Organizations that anticipate and adapt to these changes position themselves for long-term success.

Maintaining market responsiveness demands continuous research and flexible operational strategies capable of adjusting to fluctuating demand patterns.

The Power of Strategic Collaboration

Effective partnerships enhance supply chain resilience and efficiency. Cooperative relationships that share knowledge and resources create mutual benefits across organizations.

Successful collaboration depends on clear communication, aligned objectives, and commitment to shared success.

Mitigating Operational Risks

Modern supply chains face numerous potential disruptions. Proactive risk identification and management are critical for maintaining business continuity.

Risk reduction strategies include supplier diversification and geographic distribution of operations. Developing comprehensive contingency plans builds organizational resilience.

The Future Landscape of Supply Chains

Tomorrow's supply networks will increasingly rely on automation and data-driven decision making. Companies embracing these trends will lead in efficiency and sustainability.

Emerging technologies like blockchain promise enhanced transparency and traceability throughout global supply networks.