Improving Aircraft Reliability

Predictive maintenance, powered by AI, is revolutionizing the aerospace industry by significantly improving aircraft reliability. By analyzing vast amounts of data from various sources, including sensor readings, flight logs, and maintenance records, AI algorithms can identify subtle patterns and anomalies that might indicate potential mechanical issues before they escalate into costly and time-consuming breakdowns. This proactive approach reduces downtime, minimizes maintenance expenses, and extends the lifespan of aircraft components, leading to substantial cost savings and enhanced operational efficiency for airlines.

The ability to anticipate and address potential problems proactively translates directly into enhanced safety. Early detection of developing issues allows for timely intervention, preventing catastrophic failures that could compromise flight safety and put passengers at risk. This proactive approach, driven by AI, is a crucial step towards creating a more robust and reliable aerospace infrastructure.

Optimizing Maintenance Schedules

AI algorithms can analyze historical maintenance data and real-time operational conditions to create optimized maintenance schedules. Instead of relying on predetermined intervals, AI can identify the precise moment when a component requires maintenance based on its actual usage and condition. This precision leads to reduced unnecessary maintenance, saving time and resources, while ensuring that critical components are serviced only when necessary.

This optimized approach also minimizes costly downtime by preventing unexpected failures. By proactively scheduling maintenance based on real-time data, airlines can avoid disruptions to their flight schedules and ensure smooth operations. The intelligent scheduling facilitated by AI results in a significant reduction in operational costs and a considerable improvement in overall efficiency.

Enhancing Data-Driven Decision Making

The core of predictive maintenance lies in leveraging data. AI excels at extracting meaningful insights from complex datasets. By analyzing data from various sources, including sensor readings, flight patterns, and operational conditions, AI can identify subtle trends and anomalies that might indicate potential issues long before they manifest as visible problems. This predictive capability allows for proactive decision-making, enabling airlines to allocate resources more effectively and optimize their maintenance strategies.

Data-driven decision-making, enabled by AI, empowers maintenance teams with critical insights into the health and performance of their aircraft. This allows them to make informed choices about maintenance priorities, resource allocation, and overall operational strategy. The result is a more efficient and effective maintenance process that minimizes downtime, reduces costs, and ultimately improves the safety and reliability of the entire aerospace operation. This predictive approach, fundamentally data-driven, is integral to the future of aerospace maintenance.

Optimizing Maintenance Schedules and Resource Allocation

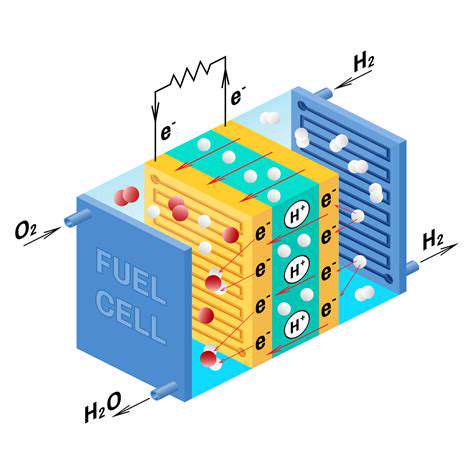

Predictive Maintenance Models

Implementing AI-powered predictive maintenance models allows aerospace companies to anticipate potential equipment failures before they occur. These models analyze vast datasets of sensor data, flight logs, and maintenance records to identify patterns and anomalies that signal impending issues. This proactive approach minimizes downtime, reduces repair costs, and enhances the overall safety and reliability of aircraft operations. Predictive maintenance models are crucial for optimizing maintenance schedules, as they empower companies to schedule maintenance tasks based on the actual needs of the equipment rather than rigid timelines.

By leveraging machine learning algorithms, these models can identify subtle indicators of wear and tear that might be missed by traditional methods. This early detection capability is critical in preventing catastrophic failures and ensuring the safety of personnel and passengers.

Resource Allocation Strategies

AI algorithms can optimize resource allocation by analyzing factors such as technician skill sets, equipment availability, and the urgency of maintenance tasks. This analysis allows for the most efficient allocation of resources, ensuring that the right technicians are assigned to the right jobs at the right time. By leveraging AI, aerospace companies can streamline their maintenance processes and reduce unnecessary costs associated with inefficient resource utilization.

Furthermore, AI can predict future resource needs, allowing companies to proactively adjust staffing levels and procurement strategies to meet anticipated demands. This proactive approach enhances the responsiveness and flexibility of the maintenance operation, crucial for adapting to changing operational needs.

Enhanced Maintenance Scheduling

AI-driven maintenance scheduling systems can dynamically adjust maintenance schedules based on real-time data and predicted equipment conditions. This approach eliminates the need for rigid, time-based maintenance schedules, which can be inefficient and costly. By incorporating predictive maintenance models, these systems can optimize maintenance schedules to minimize downtime and maximize operational efficiency.

The flexibility of AI-powered scheduling enables companies to respond promptly to critical maintenance needs, ensuring the safety and reliability of aircraft. This dynamic approach to scheduling can significantly reduce operational costs and improve the overall performance of the maintenance department.

Data Collection and Integration

Effective AI implementation in aerospace maintenance hinges on robust data collection and integration strategies. Gathering comprehensive data from various sources, including sensor readings, flight logs, and maintenance records, is paramount. This data must be seamlessly integrated into a centralized system to enable AI algorithms to analyze it effectively. Data quality is critical for the accuracy and reliability of AI-driven insights.

Data integrity and security are also crucial aspects of this process. Implementing robust data management procedures and security protocols safeguards sensitive information and ensures the reliability of the AI-driven insights. This will provide a solid foundation for accurate maintenance predictions and optimized resource allocation.

Improving Maintenance Staff Training and Skills

AI tools can be used to create tailored training programs for maintenance personnel. These programs can identify skill gaps and provide targeted training resources to enhance their proficiency in utilizing AI-driven tools and technologies. By improving the skills and knowledge of maintenance staff, aerospace companies can further optimize the efficiency and effectiveness of their maintenance operations.

AI-driven training systems can also provide personalized feedback and guidance to maintenance technicians, fostering continuous learning and improvement. This continuous improvement approach is key to staying ahead of evolving maintenance challenges and leveraging the full potential of AI in aerospace maintenance.

Improving Data Analysis and Decision-Making

Leveraging AI for Predictive Maintenance

Artificial intelligence (AI) is revolutionizing aerospace maintenance operations by enabling predictive maintenance strategies. AI algorithms can analyze vast amounts of data from various sources, including sensor readings, maintenance records, and flight logs, to identify patterns and predict potential equipment failures before they occur. This proactive approach minimizes downtime, reduces repair costs, and enhances operational efficiency. By anticipating maintenance needs, AI-powered systems can schedule maintenance activities optimally, aligning with flight schedules and minimizing disruptions to operations.

Optimizing Maintenance Schedules with AI

Traditional maintenance schedules often rely on predefined intervals, which can lead to either unnecessary maintenance or costly equipment failures due to inadequate preventative measures. AI algorithms can analyze the specific operational conditions of each aircraft, considering factors like flight duration, environmental conditions, and flight path, to tailor maintenance schedules. This personalized approach ensures that maintenance is performed only when necessary, maximizing the lifespan of aircraft components and minimizing operational costs.

By incorporating real-time data and performance metrics, AI algorithms can dynamically adjust maintenance schedules, responding to unusual wear and tear or emerging maintenance needs. This adaptability is crucial for maintaining high operational readiness and ensuring safety standards are consistently met.

Enhancing Data Collection and Management

AI plays a pivotal role in enhancing data collection and management within aerospace maintenance. Advanced sensor technologies generate copious amounts of data, which, if not effectively collected, stored, and analyzed, can be overwhelming. AI-powered systems can streamline this process, automating data ingestion, cleaning, and validation. This ensures that only reliable and accurate data is used for analysis, leading to more precise maintenance predictions and improved decision-making.

Improving Fault Diagnosis and Root Cause Analysis

AI algorithms can analyze maintenance data to identify complex patterns and anomalies that might indicate potential faults. Furthermore, AI can expedite the root cause analysis process, pinpointing the exact reason behind equipment failures. This capability enables engineers to quickly diagnose the issue, implement corrective actions, and prevent similar failures from occurring in the future. This proactive approach to fault diagnosis helps reduce downtime and enhances the overall safety and reliability of aircraft operations.

Improving Resource Allocation and Cost Optimization

AI-driven insights into maintenance needs can optimize resource allocation, ensuring that the right personnel and parts are available when and where they are needed. By analyzing historical data and current operational demands, AI algorithms can predict maintenance requirements and allocate resources accordingly. This optimization translates into significant cost savings, as it minimizes unnecessary inventory levels and reduces the risk of delays or disruptions. Moreover, optimized resource allocation helps enhance overall operational efficiency, enabling airlines to maintain a competitive edge in the aerospace industry.

Enhanced Safety and Reduced Downtime Through AI-Powered Monitoring

Improved Safety Protocols

Implementing enhanced safety protocols is crucial for minimizing workplace accidents and injuries. These protocols should encompass a comprehensive approach to hazard identification, risk assessment, and mitigation strategies. This proactive approach will not only safeguard employees but also contribute to a more productive and efficient work environment. Thorough training on safety procedures and equipment usage is essential to ensure employees understand and adhere to the protocols.

Regular safety audits and inspections are necessary to identify potential hazards and ensure that safety measures remain effective. Furthermore, a culture of safety, where employees feel comfortable reporting concerns and participating in safety initiatives, is vital for maintaining a secure and healthy work environment. This culture of safety must be fostered through clear communication and consistent reinforcement of safety protocols.

Reduced Maintenance Costs

Implementing proactive maintenance strategies can significantly reduce the frequency and severity of equipment breakdowns. Predictive maintenance, which involves monitoring equipment performance and identifying potential issues before they escalate, is a key element in this approach. This proactive strategy can lead to substantial cost savings by preventing costly repairs and downtime.

Regular preventative maintenance schedules, performed by qualified technicians, can also minimize the risk of major breakdowns. By addressing minor issues promptly, we can prevent them from developing into more significant and costly problems. This proactive maintenance approach ensures that equipment operates at optimal efficiency, minimizing unexpected downtime and associated expenses.

Enhanced Operational Efficiency

The integration of modern technologies, such as automation and advanced data analytics, can optimize operational processes and increase efficiency. This includes using real-time data to monitor equipment performance, identify bottlenecks, and optimize workflows. Improved efficiency translates directly into reduced operational costs and increased productivity.

Streamlining processes and eliminating redundant steps can also contribute to significant gains in operational efficiency. This process involves analyzing existing procedures, identifying areas for improvement, and implementing solutions to optimize workflow. These improvements can lead to faster turnaround times and greater output without increasing labor costs.

Minimized Downtime

Proactive maintenance and robust safety procedures are essential for minimizing unplanned downtime. This approach includes scheduling maintenance activities during off-peak hours, implementing backup systems for critical equipment, and ensuring readily available spare parts. All these measures contribute to a smoother and more predictable workflow.

Implementing a system for rapid response to equipment failures can significantly reduce the duration of downtime. This involves having trained personnel and readily available parts to address problems immediately, minimizing disruption to the production schedule. These measures are vital for maintaining productivity and meeting production targets. Rapid response and proactive measures greatly reduce the impact of unexpected failures.

Improved Employee Morale

A safe and efficient work environment contributes significantly to improved employee morale and job satisfaction. Employees who feel valued and protected are more likely to be engaged and productive. This positive work environment fosters a culture of collaboration and innovation.

A sense of security and trust in the workplace promotes a positive and productive work environment. When employees feel safe, they are more likely to take initiative, collaborate effectively, and contribute their best work. This positive atmosphere results in higher job satisfaction and retention rates.