Challenges in Implementing Space-Based Biomanufacturing

Resource Constraints in Space

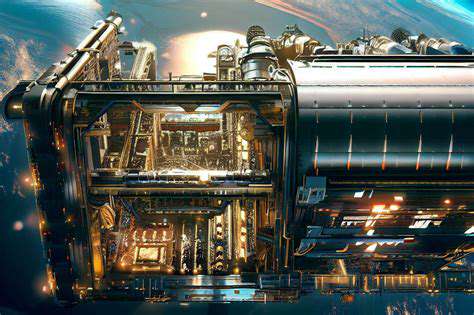

One of the most pressing issues facing space-based biomanufacturing revolves around the scarcity of essential resources. Transporting necessary materials like raw components and specialized reagents to space stations or lunar bases proves both costly and logistically demanding due to payload limitations. This reality forces engineers to develop ultra-efficient production methods that maximize output while minimizing input requirements. The inability to easily replenish supplies in orbit underscores the critical need for closed-loop, self-sustaining manufacturing systems.

Establishing reliable supply chains for biological materials presents another formidable obstacle. The vast distances and inherent risks of space transport demand redundant systems, comprehensive quality controls, and innovative solutions like in-situ resource utilization. Researchers are particularly interested in developing technologies that can regenerate or synthesize critical materials on-site to reduce dependence on Earth-based supplies.

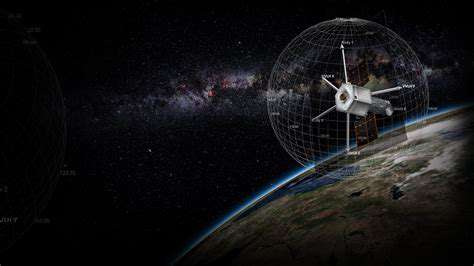

Environmental Control and Stability

Creating and maintaining optimal conditions for biological processes in space requires overcoming extreme environmental challenges. The vacuum of space, combined with intense radiation and temperature fluctuations, can severely disrupt sensitive biological systems. Engineers must design sophisticated containment systems that can precisely regulate all environmental parameters - from atmospheric composition to thermal conditions - to support manufacturing processes.

Developing robust life support architectures represents a crucial engineering challenge. These systems must not only protect biological cultures but also ensure astronaut safety while operating reliably for extended durations without maintenance. The integration of fail-safes and redundant subsystems becomes particularly vital in the harsh space environment.

Scale-Up and Process Optimization

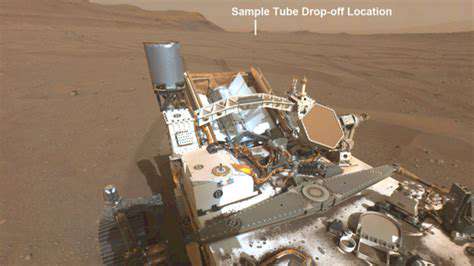

Transitioning from small-scale laboratory prototypes to full production capacity in space introduces numerous technical complications. The absence of gravity significantly alters fluid dynamics and material behaviors, requiring complete re-engineering of terrestrial manufacturing processes. Scientists must develop novel bioreactor designs and processing methods specifically optimized for microgravity conditions while maintaining stringent quality standards.

Equipment Reliability and Maintenance

The remoteness of space operations demands exceptionally durable and low-maintenance equipment designs. Manufacturing systems must incorporate robust construction and extensive redundancy to ensure continuous operation despite the challenges of the space environment. Engineers prioritize designs that minimize moving parts and incorporate self-diagnostic capabilities to predict and prevent failures before they occur.

The development of autonomous repair systems and modular component designs could significantly reduce dependence on human intervention for maintenance. Such innovations would prove particularly valuable for long-duration missions where resupply or repair missions prove impractical.

Contamination Control and Sterilization

Maintaining sterile manufacturing environments in space requires overcoming unique challenges. The absence of atmospheric pressure and presence of cosmic radiation create unusual contamination vectors not encountered on Earth. Researchers are developing specialized sterilization techniques that can operate effectively in vacuum conditions while remaining safe for biological materials.

Advanced monitoring systems capable of detecting microbial contamination at extremely low thresholds are under development. These systems must integrate seamlessly with purification protocols to maintain manufacturing integrity throughout extended production cycles.

Human Factors and Crew Training

The human element introduces additional complexity to space-based manufacturing operations. Astronauts require extensive training to operate specialized equipment while adhering to strict sterile protocols in confined spaces. Ergonomics and human-machine interfaces become critical design considerations to minimize errors and maximize efficiency in the challenging space environment.

Psychological factors must also be addressed, as crews working in isolation for extended periods face unique stressors. Developing effective team dynamics and maintaining morale becomes as important as technical considerations for mission success.

Potential Applications in Regenerative Medicine and Therapeutics

Space-Based Manufacturing of Biomaterials for Tissue Engineering

The microgravity conditions found in space enable the creation of biomaterials with structural properties impossible to achieve terrestrially. Researchers can produce tissue scaffolds with precisely controlled porosity and architecture that more closely mimic natural extracellular matrices. This capability could revolutionize regenerative medicine by enabling the creation of implantable structures that better support cellular ingrowth and tissue regeneration.

Space manufacturing also offers potential advantages in product consistency and purity by eliminating many terrestrial contamination sources. The controlled environment may allow production of biomedical materials with more reproducible characteristics and fewer batch-to-batch variations.

Advanced Drug Delivery Systems for Space Exploration and Treatment

Microgravity enables novel approaches to pharmaceutical manufacturing, particularly for complex drug delivery systems. Scientists can create sophisticated carrier mechanisms with precisely engineered release profiles that could improve treatment efficacy while reducing side effects. Such systems could prove invaluable for managing astronaut health during long-duration missions while also offering therapeutic advances for terrestrial medicine.

The ability to manufacture personalized medication formulations on-demand in space could transform treatment approaches. This capability would be particularly valuable for addressing the unique health challenges faced by astronauts during extended space missions.

Manufacturing of Novel Regenerative Therapies for Space Missions

Space-based production could enable revolutionary approaches to treating injuries and degenerative conditions encountered during spaceflight. Technologies like bioprinting could allow for on-site generation of replacement tissues or organs tailored to individual astronauts' needs. Similarly, advanced biomaterial production could support bone regeneration and wound healing in the challenging space environment.

Developing these capabilities would significantly reduce mission mass requirements by decreasing dependence on pre-supplied medical resources. More importantly, it could provide astronauts with access to cutting-edge treatments that improve mission safety and crew health outcomes.

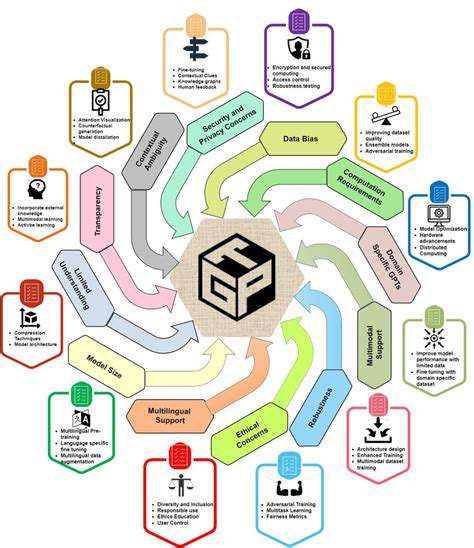

Addressing Challenges in Space-Based Biomanufacturing

While the potential benefits are substantial, significant technical hurdles remain before space-based biomanufacturing becomes routine. Process validation and quality control present particular challenges in the space environment, requiring new standards and testing protocols. Cost-effectiveness analyses must demonstrate clear advantages over terrestrial alternatives to justify the substantial investment required.

The development of autonomous robotic systems capable of performing delicate biological manipulations will be crucial for scaling operations. Regulatory frameworks must also evolve to address the unique aspects of space-manufactured biomedical products while ensuring patient safety.

The Future of Biomedical Production in Space

Advanced Manufacturing Techniques

Emerging technologies are transforming biomedical production capabilities both on Earth and in space. Additive manufacturing enables creation of complex, patient-specific medical devices with precision impossible through traditional methods. This technology allows for integration of multiple functions within single components, reducing assembly requirements and potential failure points.

Microfluidic systems and nanotechnology are enabling new approaches to diagnostics and drug delivery. These technologies benefit significantly from microgravity conditions, which eliminate sedimentation and convection effects that complicate terrestrial manufacturing processes.

Personalized Medicine and Customization

The convergence of biotechnology and advanced manufacturing is driving medicine toward truly personalized treatment paradigms. The ability to produce therapies tailored to individual genetic profiles and physiological characteristics represents a fundamental shift in healthcare delivery. Space-based manufacturing could accelerate this trend by enabling production modalities not feasible under Earth's gravity.

This personalized approach requires flexible manufacturing systems capable of producing small batches with high precision. Developing such systems for space applications presents substantial engineering challenges but offers potentially transformative benefits for both space and terrestrial medicine.

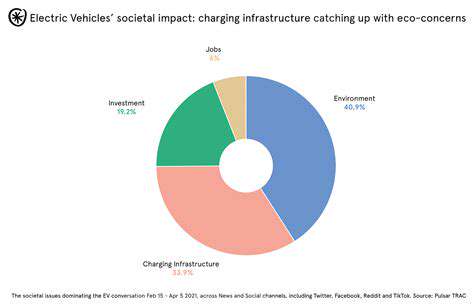

Sustainable Practices and Ethical Considerations

As space-based biomedical production develops, sustainability must remain a core consideration. Closed-loop systems that minimize waste and maximize resource efficiency will be essential for long-term viability. Ethical frameworks must address questions of equitable access and appropriate use of these advanced technologies.

Transparent development processes and inclusive policy discussions will be crucial for ensuring these innovations benefit humanity broadly. This includes addressing potential dual-use concerns and establishing international cooperation frameworks for space-based biomedical research and production.