Key Advantages of Orbital Manufacturing

Reduced Material Costs

Orbital manufacturing offers the potential for significant cost reductions in material acquisition and processing. The absence of Earth's gravity allows for the use of specialized manufacturing techniques that minimize material waste and optimize resource utilization. This can lead to substantial savings compared to traditional terrestrial methods, especially for materials like metals and composites that are expensive to transport and refine on Earth.

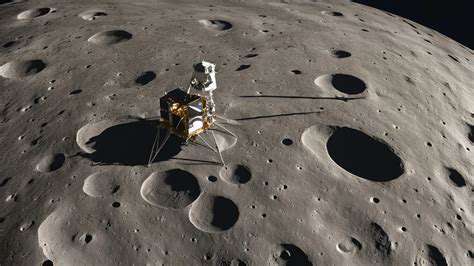

Furthermore, the ability to access and utilize readily available materials in space, such as asteroids and lunar regolith, drastically reduces the need to transport resources from Earth. This drastically reduces transportation costs and logistical complexities, making the final product more affordable.

Enhanced Production Efficiency

Space-based manufacturing facilities can operate 24/7 without the limitations of Earth-based production cycles, such as weather patterns or power outages. This continuous operation significantly increases production output and allows for more efficient allocation of resources.

By eliminating the constraints of terrestrial environments, orbital factories can achieve unparalleled levels of production efficiency, leading to faster turnaround times and higher output rates. This heightened efficiency translates to quicker delivery of products and a faster response to market demands.

Improved Safety and Security

Manufacturing in a space environment can mitigate significant safety concerns associated with terrestrial production. Hazardous materials can be handled in a controlled and isolated environment, reducing risks to workers and the surrounding environment.

Additionally, orbital factories can be strategically located to minimize the impact of natural disasters or geopolitical instability. This enhances the security of the production process and ensures reliable access to resources.

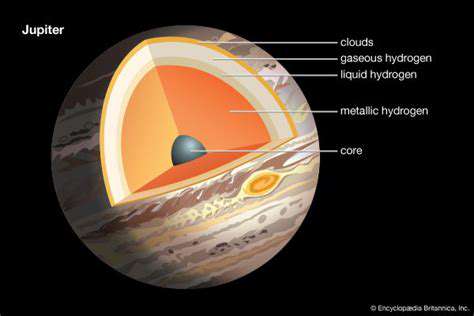

Access to Unique Resources

Space offers access to a wide range of unique resources not readily available on Earth, such as certain types of asteroids and lunar regolith. These resources can be used to produce materials with enhanced properties, leading to innovative and high-performance products.

The availability of these specialized resources unlocks possibilities for creating advanced materials and technologies that are currently impossible to achieve on Earth. This opens up entirely new avenues for innovation and technological advancement.

Minimized Environmental Impact

Orbital manufacturing, by its very nature, minimizes environmental impact on Earth. This reduces the pollution and resource depletion associated with traditional manufacturing processes. Reduced reliance on Earth-based resources directly translates to a lower carbon footprint, contributing to sustainability efforts. Moreover, the ability to process materials in space can lessen the strain on Earth's finite resources.

Minimized waste and optimized resource use are also key aspects of orbital manufacturing's environmental benefits. By eliminating transportation needs, and using materials more efficiently, orbital factories can reduce the overall environmental footprint.

Reduced Manufacturing Costs

Orbital manufacturing facilities can significantly reduce the cost of manufacturing certain products by eliminating the need for extensive transportation networks. The absence of Earth's gravity allows for specialized production processes that minimize material waste and optimize resource utilization.

The reduced transportation costs and logistics inherent in orbital manufacturing are significant factors in lowering the overall cost of production. This lower cost structure can translate into more competitive pricing for consumers and increased profitability for manufacturers.

Potential Applications and Products

Potential Applications in Healthcare

The advancements in technology have opened up exciting new possibilities for the application of this product in healthcare. This innovative technology has the potential to revolutionize patient care by providing more accessible and accurate diagnostic tools. Early detection of diseases, personalized treatment plans, and remote patient monitoring are just a few of the promising applications that this product could bring to the field. This could lead to significant improvements in patient outcomes and reduce the overall cost of healthcare.

Imagine a future where patients can receive timely and accurate diagnoses from the comfort of their own homes, thanks to this advanced technology. This would not only improve patient convenience but also enable earlier intervention, potentially saving lives.

Applications in Consumer Electronics

Beyond healthcare, the potential applications of this product extend into the consumer electronics sector. Integrating this technology into everyday devices could usher in a new era of personalized experiences, from smart home appliances to entertainment systems. Enhancing the user experience through tailored recommendations and intelligent control systems is a significant possibility. Imagine devices automatically adjusting to your preferences based on your usage patterns, creating a truly seamless and intuitive experience.

The product's potential in personal entertainment is also substantial. This technology could revolutionize how we consume media, with personalized recommendations and interactive experiences. Imagine a future where entertainment is not only engaging but also truly tailored to each individual's preferences.

Applications in Industrial Automation

The potential applications of this product also extend to the industrial sector, particularly in automation and process control. This technology could improve efficiency and productivity in manufacturing and industrial settings. Real-time monitoring and analysis of machine performance can lead to predictive maintenance, minimizing downtime and maximizing output. This would dramatically increase the efficiency of production processes.

Further, this product could contribute to the development of more sophisticated and adaptable automation systems. By creating systems that can learn and adapt to changing circumstances, manufacturers can optimize their production lines in real-time and significantly increase their overall productivity. This could lead to a more streamlined and efficient industrial landscape.

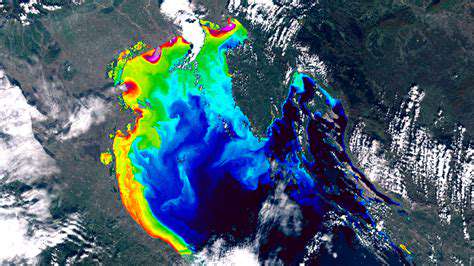

Applications in Environmental Monitoring

This product's capabilities also have significant implications for environmental monitoring. Deploying this technology in environmental monitoring systems could provide valuable insights into various environmental parameters. Real-time data collection and analysis could aid in understanding and addressing climate change and pollution issues. This could enable more accurate forecasts, leading to proactive environmental management.

The potential for early detection of environmental hazards is substantial, enabling quicker responses and minimizing damage. This technology could also contribute to the development of sustainable practices, allowing for more informed decision-making in environmental protection efforts.