Exploring the Versatility of Composite Materials

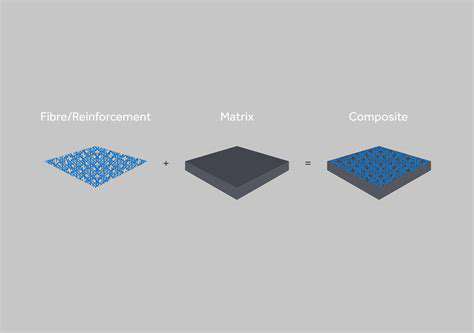

Composite materials are a fascinating class of materials that combine the desirable properties of two or more constituent materials to create a superior product. This unique approach allows engineers and designers to tailor the final material to specific needs, achieving a balance of strength, lightness, durability, and cost-effectiveness. By carefully selecting the matrix and reinforcement phases, manufacturers can optimize the characteristics of the composite to meet demanding requirements in various sectors.

One key advantage of composite materials lies in their exceptional strength-to-weight ratio. This property makes them particularly attractive for applications where lightweight yet robust components are essential. For instance, in aerospace engineering, composite materials are increasingly replacing traditional metallic alloys, leading to significant improvements in fuel efficiency and performance.

The versatility of composite materials extends far beyond aerospace applications. They are also finding widespread use in automotive manufacturing, construction, and sporting goods. The diverse possibilities for material customization allow for a wide range of applications, from high-performance sports equipment to structural components in bridges and buildings.

Manufacturing and Applications of Composite Materials

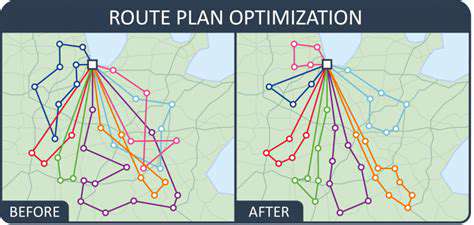

The manufacturing processes for composite materials are often complex, requiring specialized techniques to ensure the desired properties are achieved. These processes can range from simple layering techniques to sophisticated automated systems, depending on the specific application and required performance characteristics. Understanding these manufacturing processes is crucial for optimizing the final product and ensuring its quality and longevity.

Composite materials are being used in a growing number of applications due to their ability to meet specific performance criteria. Their unique properties are enabling advancements in various industries, such as the construction of stronger and lighter bridges, the creation of more fuel-efficient vehicles, and the development of high-performance sporting equipment. This trend is expected to continue as research and development in composite materials continue to advance.

The use of composites in construction is particularly noteworthy. Their high strength-to-weight ratio allows for the creation of lightweight yet robust structural elements, leading to significant cost savings and reduced environmental impact. Moreover, the inherent design flexibility of composite materials opens up new possibilities for innovative architectural designs.

Furthermore, the ability to tailor the properties of composite materials allows for a wide range of applications in the medical field, from lightweight implants to advanced prosthetics. This adaptability and precision manufacturing are driving the development of innovative solutions in diverse fields.

Advanced Metals and Alloys: Enhancing Existing Technologies

Advanced Properties of Advanced Metals

Advanced metals and alloys exhibit a range of exceptional properties, surpassing those of traditional materials. These enhanced characteristics are crucial in various applications, from aerospace engineering to medical implants. The strength-to-weight ratio of these alloys is often significantly higher than conventional metals, allowing for lighter and more efficient designs. This is particularly important in industries demanding high performance with minimal weight, such as automotive and aviation.

Furthermore, advanced metals frequently demonstrate superior corrosion resistance, making them suitable for harsh environments. This translates to longer lifespan and reduced maintenance costs in applications exposed to corrosive agents or elements.

Enhanced Manufacturing Techniques

The production of advanced metals and alloys often necessitates specialized manufacturing techniques. These advanced processes are crucial for achieving the desired microstructures and properties. Pulverized metal injection molding, for instance, allows for the creation of complex shapes with high precision and control over the material's microstructure. This precision is important for achieving the optimal combination of mechanical, thermal, and electrical properties required in specific applications.

Another important manufacturing technique is additive manufacturing (3D printing). This method enables the creation of intricate parts with customized geometries, allowing for significant design flexibility and potentially reducing material waste.

Applications in Aerospace Engineering

The aerospace industry heavily relies on advanced metals and alloys for their exceptional strength, lightweight characteristics, and high-temperature resistance. Aircraft components, such as engine parts and fuselage sections, often utilize these materials to enhance performance and safety. The improved performance characteristics of advanced alloys can translate to improved fuel efficiency and reduced emissions.

The development of advanced alloys for aerospace applications continues to be a major focus area, aiming to push the boundaries of performance and safety in aircraft design.

Impact on Medical Implants

In the medical field, advanced metals and alloys are increasingly used for creating biocompatible implants. These materials are crucial for replacing damaged or diseased tissues, and their biocompatibility is paramount for successful long-term integration with the human body. Biocompatibility is a key factor in ensuring that the implant does not trigger an immune response or cause adverse reactions.

Role in Automotive Industry

The automotive industry is another sector that benefits significantly from the use of advanced metals and alloys. These materials are employed to create lighter and stronger components, leading to improved fuel economy and enhanced vehicle performance. Lightweight designs are crucial for achieving better fuel efficiency and reducing emissions, aligning with sustainable transportation goals. Advanced alloys are also utilized in engine components, transmissions, and chassis structures.

Advanced Materials for Energy Applications

The energy sector is increasingly exploring the potential of advanced metals and alloys for energy storage and conversion applications. These materials play a crucial role in developing more efficient and reliable energy systems. High-temperature alloys are critical for designing more efficient power generation systems, while others are being developed for advanced energy storage applications.

Future Trends and Research

Research and development in advanced metals and alloys are continuously pushing the boundaries of material science. New alloy compositions and processing techniques are being explored to achieve even better properties, such as enhanced strength, toughness, and corrosion resistance. The focus is on developing materials with optimized performance characteristics for various applications, including advanced electronics, energy storage, and defense technologies.

The ongoing pursuit of new materials and processing methodologies promises significant advancements in various industries, creating innovative solutions for future challenges.