Introduction to Lunar Regolith and its Potential

Lunar Regolith Composition

Lunar regolith, the layer of loose, powdery material covering the Moon's surface, is primarily composed of fragmented rock and mineral particles. These particles are a result of impacts from meteoroids over billions of years. The composition of this regolith varies depending on the specific location on the Moon, reflecting the diverse geological history of different regions.

Significant components include feldspar, pyroxene, and olivine, remnants of the Moon's primordial mantle. The presence of these minerals provides crucial insights into the Moon's formation and early evolution. Trace amounts of other elements, including titanium and iron, also contribute to the regolith's overall chemical makeup.

Formation and Characteristics

The formation of lunar regolith is a continuous process driven by the relentless bombardment of micrometeoroids and larger impactors. This constant barrage pulverizes surface materials, creating a fine-grained, highly fragmented layer. The lack of atmosphere and weather on the Moon allows this material to accumulate and remain undisturbed for extended periods.

This unique process results in regolith with distinctive characteristics, including a very low density and a high porosity. The low density is a direct consequence of the highly fragmented nature of the material. The high porosity allows it to retain gases and volatiles, such as water ice, trapped within its complex structure, especially in permanently shadowed craters.

Geological Significance

The study of lunar regolith is of immense geological significance. It provides valuable clues about the Moon's history, including its formation, the nature of the impactors that bombarded it, and the processes that shaped its surface over billions of years. Analysis of the regolith samples returned by Apollo missions has revolutionized our understanding of the Moon's composition and evolution.

Potential Resources

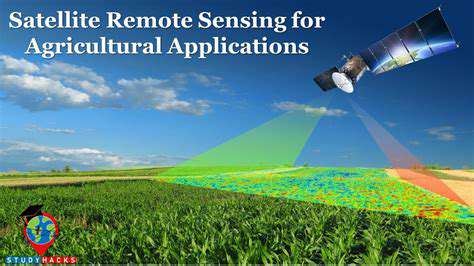

Lunar regolith may hold valuable resources for future lunar exploration and utilization. Water ice, potentially trapped within the regolith in permanently shadowed craters, could serve as a source of drinking water, rocket propellant, and even oxygen for future lunar bases. Furthermore, the regolith itself may be used as a construction material for habitats and infrastructure, reducing the need to transport materials from Earth.

Exploration and Applications

The exploration of lunar regolith is ongoing, with various missions dedicated to studying its properties and potential applications. These investigations aim to determine the precise distribution and abundance of valuable resources. Future research will focus on developing technologies for extracting and utilizing these resources, paving the way for sustainable human presence on the Moon. Furthermore, the study of regolith will provide vital data for predicting the effects of future space activities on lunar environments.

Challenges and Opportunities in Regolith Processing

Challenges in Regolith Processing

Processing lunar regolith presents a multitude of challenges, from the unique physical and chemical properties of the material to the logistical hurdles of operating in a vacuum environment. The inherent heterogeneity of lunar regolith, containing varying proportions of fine dust, rocks, and glass particles, necessitates sophisticated separation and purification techniques. Developing robust and reliable equipment capable of functioning under extreme temperature fluctuations and in the absence of atmospheric pressure is crucial. Furthermore, the potential for radiation damage to processing equipment and the safety of astronauts working in the harsh lunar environment must be meticulously considered.

The presence of potentially hazardous materials, such as trace elements or radioactive isotopes, poses significant risks to both equipment and human health. Thorough characterization and analysis of the regolith composition are essential before any processing operations commence. Developing robust safety protocols and handling procedures is paramount to mitigating these risks and ensuring the long-term sustainability of lunar resource utilization.

Opportunities in Regolith Processing

Despite the challenges, the opportunities presented by lunar regolith processing are substantial. The abundance of raw materials present in the regolith, including metals, minerals, and volatiles, could potentially provide resources for constructing habitats, life support systems, and even fuel for future lunar missions. This in-situ resource utilization (ISRU) offers significant cost savings and logistical advantages compared to transporting all necessary resources from Earth.

Furthermore, the development of regolith processing technologies could pave the way for advanced manufacturing techniques, creating new possibilities for the production of various materials on the Moon. This could lead to the establishment of a self-sufficient lunar economy, reducing reliance on Earth-based resources and opening up new possibilities for scientific discovery and technological advancement.

Technological Advancements in Regolith Processing

Significant advancements in materials science, robotics, and automation are crucial for overcoming the challenges of regolith processing. The development of specialized equipment capable of handling the unique properties of lunar regolith, such as advanced separation techniques and efficient processing methods, is essential. Research into alternative energy sources and sustainable processing methods is also vital for minimizing the environmental impact of lunar operations.

Economic Considerations in Regolith Processing

The economic viability of regolith processing is a critical factor in determining its feasibility. The costs associated with transporting materials from Earth to the Moon are substantial, making in-situ resource utilization a potentially attractive alternative. Evaluating the costs of developing and deploying processing technologies, as well as the potential return on investment, is essential for ensuring economic viability. Furthermore, establishing a robust market for lunar resources and developing sustainable business models are critical to fostering the growth of a lunar economy.

Environmental Impacts of Regolith Processing

The environmental impact of regolith processing on the lunar surface must be carefully considered. Potential consequences, such as the generation of waste materials, the alteration of the lunar landscape, and the introduction of contaminants to the lunar environment, must be minimized. Implementing stringent environmental regulations and developing environmentally friendly processing techniques are vital for ensuring the long-term sustainability of lunar operations. Careful consideration of the potential impact on lunar resources and ecosystems is crucial to avoid unintended consequences.

3D Printing Techniques for Lunar Regolith Applications

Direct Energy Deposition (DED)

Direct Energy Deposition (DED) is a laser-based additive manufacturing technique that's well-suited for creating complex, high-strength components on the lunar surface. This process involves precisely melting and depositing material layer by layer. DED offers the potential for producing parts with intricate geometries and high dimensional accuracy, crucial for constructing specialized equipment and tools on the moon.

By utilizing DED, lunar outposts can potentially fabricate customized structural elements, enabling the construction of robust habitats and infrastructure. This technique significantly reduces the need for transporting large quantities of pre-fabricated components from Earth, thereby minimizing risks and costs associated with lunar logistics.

Stereolithography (SLA)

Stereolithography (SLA) is a vat-based 3D printing technique that uses a liquid resin and a UV laser to solidify material layer by layer. SLA technology is particularly suitable for producing intricate shapes and small-scale parts within confined environments. This method could be invaluable for creating precise components for lunar scientific instruments and experiments.

The ability to produce highly detailed parts with SLA is a significant advantage, enabling the fabrication of complex components for lunar rovers, habitats, or specialized scientific equipment. Using this technique on the moon will allow scientists and engineers to quickly iterate on designs and create prototypes without the need for extensive transportation and logistical support.

Selective Laser Melting (SLM)

Selective Laser Melting (SLM) is a powder-bed fusion process that utilizes a high-powered laser to melt and fuse metallic powders layer by layer. SLM is capable of producing complex geometries and high-strength components, making it a strong candidate for constructing robust lunar infrastructure. This method is particularly effective for producing components that require high levels of strength and durability, such as structural beams and support frames.

The high-quality, dense parts produced by SLM are ideal for use in critical structures and functional components. This method holds significant promise for constructing lunar habitats, scientific stations, and other critical infrastructure.

Material Extrusion

Material extrusion, a common 3D printing method, involves extruding heated filament or material through a nozzle to form layers. While not as precise as some other techniques, material extrusion is relatively simple to implement and can be utilized for rapid prototyping and the creation of basic structures. Its simplicity and relative ease of operation make it a potentially valuable tool for rapid fabrication of lunar components. This technique could be effective for creating functional prototypes or smaller-scale parts.

This method is particularly well-suited for quick manufacturing of simple parts and prototypes for testing purposes, and can be a valuable tool for engineers and scientists on the lunar surface. This method is often preferred for its ease of use and cost-effectiveness.

Laminated Object Manufacturing (LOM)

Laminated Object Manufacturing (LOM) is a sheet-based 3D printing process that uses layers of material to construct objects. LOM is particularly suitable for creating complex shapes and parts with varying thicknesses and features. This method is a viable option for producing parts that require specific structural properties and material configurations. This process can produce functional components for lunar exploration, including those for scientific instruments and specialized equipment.

LOM offers the advantage of using readily available materials and creating complex shapes. This makes it a potential candidate for constructing lunar structures and equipment, allowing engineers to customize parts and adapt them to the specific needs of lunar missions.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a popular method used for creating plastic parts. FDM, using a heated nozzle to melt and deposit plastic filament, is known for its relatively low cost and ease of use. This method could be employed for creating functional prototypes and low-complexity parts on the lunar surface. FDM's affordability and relative simplicity make it a good candidate for early-stage lunar 3D printing applications.

FDM's accessibility and relative affordability make it a strong contender for rapid prototyping and the creation of simple parts. This technique can be beneficial for early lunar construction projects and experimentation.