AI-powered predictive maintenance represents a significant paradigm shift in industrial maintenance strategies. Instead of relying on reactive or preventative maintenance schedules, which often result in costly downtime and unnecessary repairs, this approach leverages data analysis and machine learning algorithms to anticipate potential equipment failures. This proactive approach can lead to substantial cost savings and increased operational efficiency.

By anticipating failures before they occur, organizations can minimize disruptions to production processes, reduce maintenance costs, and extend the lifespan of their equipment. This shift towards a predictive model is driven by the growing availability of data from various sources, such as sensors, operational logs, and historical maintenance records.

Data Collection and Analysis

A crucial element of AI-powered predictive maintenance is the collection and analysis of vast amounts of data. This data, often originating from various sources within the industrial environment, can include sensor readings, operational logs, and historical maintenance records. Careful consideration must be given to data quality and consistency, ensuring that the collected information is reliable and accurately reflects the machine's performance.

Sophisticated algorithms are then applied to this data to identify patterns, anomalies, and potential failure points. This analysis allows for the creation of predictive models that can forecast future equipment failures with a high degree of accuracy.

Machine Learning Algorithms at Work

Machine learning algorithms play a central role in AI-powered predictive maintenance. These algorithms are trained on historical data to recognize patterns and anomalies that indicate potential equipment failures. Different machine learning techniques, such as regression, classification, and clustering, can be employed, each with its own strengths and weaknesses in specific contexts.

The accuracy and reliability of these predictive models are directly influenced by the quality and quantity of the training data, highlighting the importance of robust data collection and management strategies. Moreover, the continuous improvement of these algorithms through ongoing data input and refinement further enhances their predictive capabilities.

Real-World Applications

AI-powered predictive maintenance is rapidly finding applications across numerous industries, including manufacturing, energy production, and transportation. In manufacturing, for example, predictive models can anticipate equipment breakdowns, allowing for proactive maintenance and minimizing production disruptions.

In energy production, this technology can optimize maintenance schedules, reducing downtime and enhancing operational efficiency. Predictive maintenance is also transforming fleet management in transportation, by enabling proactive maintenance on vehicles and reducing unexpected breakdowns.

Cost Savings and Operational Efficiency

The significant advantages of AI-powered predictive maintenance extend beyond the realm of reduced downtime. By proactively addressing potential equipment failures, organizations can significantly reduce maintenance costs. This is achieved through minimizing the need for unplanned repairs, which are often more expensive than scheduled maintenance.

Improved operational efficiency is another key benefit, as predictive maintenance enables organizations to optimize production schedules and minimize disruptions. By anticipating and preventing equipment failures, businesses can enhance their overall productivity and profitability.

The Future of Aerospace Data Analytics with AI

Advanced Data Acquisition Techniques

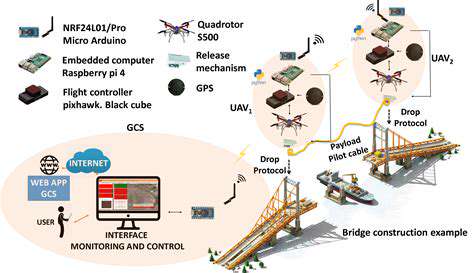

The future of aerospace data analysis hinges on the ability to gather vast quantities of high-quality data from increasingly sophisticated sensors and platforms. This includes not only traditional flight data but also information from environmental monitoring systems, satellite imagery, and even data generated by on-board AI systems. Developing new, more efficient data acquisition methods is crucial for capturing the intricate details necessary for accurate analysis and decision-making in complex aerospace scenarios. These advancements will require significant investment in cutting-edge sensor technology and robust data transmission protocols.

Furthermore, integrating diverse data sources will be essential. For instance, combining flight data with weather patterns and terrain information will provide a more comprehensive understanding of flight performance and safety. This integrated approach will enhance the predictive capabilities of aerospace data analysis.

Machine Learning Applications

Machine learning algorithms will play a pivotal role in extracting insights from the massive datasets generated by modern aerospace operations. These algorithms can identify patterns and anomalies in real-time, enabling proactive maintenance, optimized flight paths, and improved safety protocols. Moreover, machine learning models can predict potential issues before they occur, allowing for preventative measures and minimizing downtime.

Predictive Modeling and Simulation

Predictive modeling and simulation will become increasingly important for aerospace data analysis. These tools will allow engineers and researchers to simulate various scenarios, such as different weather conditions or unexpected mechanical failures, to assess their impact on flight performance and safety. This proactive approach to risk assessment will enable the development of more robust and reliable aerospace systems.

By simulating a multitude of potential situations, aerospace engineers will gain a deeper understanding of system behavior under stress, enabling them to design safer and more efficient aircraft and spacecraft. This predictive capability will be essential for optimizing designs and ensuring safety under extreme conditions.

Data Visualization and Interpretation

Effective visualization and interpretation of aerospace data are crucial for deriving meaningful insights. Interactive dashboards and graphical representations will allow stakeholders to quickly grasp complex data patterns and identify potential issues or trends. This intuitive approach will facilitate better communication and collaboration among engineers, pilots, and other stakeholders.

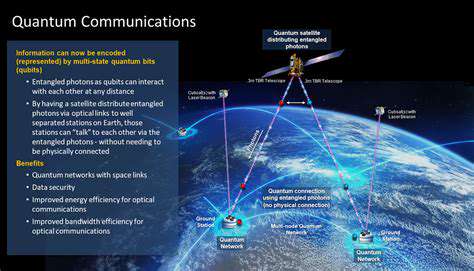

Data Security and Privacy

As aerospace data becomes increasingly valuable and complex, ensuring its security and privacy will be paramount. Robust security measures will need to be implemented to protect sensitive information from unauthorized access or manipulation. Protecting sensitive data is vital for maintaining trust and integrity within the aerospace industry. This includes implementing stringent access controls, encryption protocols, and data anonymization techniques.

Enhanced Collaboration and Communication

The future of aerospace data analysis relies heavily on seamless collaboration and communication among various stakeholders. Cloud-based platforms and collaborative tools will facilitate information sharing and knowledge exchange between engineers, researchers, and pilots. This collaborative environment will be instrumental in accelerating innovation and driving progress within the aerospace sector.

Real-Time Data Analysis and Decision-Making

Real-time analysis of aerospace data will be critical for making quick, informed decisions during flight operations. Advanced analytics tools will enable pilots and controllers to respond to unforeseen circumstances, such as unexpected weather conditions or mechanical failures. This dynamic approach to data analysis will enhance safety and improve the efficiency of aerospace operations. The ability to process data in real-time will allow for faster and more effective responses to emerging issues, ultimately leading to improved safety and reduced operational costs.